Custom Polo T-shirt Manufacturer Turkey

Custom Polo Shirt Manufacturer

Manufacturer of high quality cotton and polyester fabric embroidery Polo Shirts.

Conbello Textile produces your polo shirt designs to a high standard using high quality cotton, viscose, tencel (lyocell), micro polyester, modal and polyamide (nylon) fabrics and all printing techniques including embroidery, digital sublimation, DTF printing and silicone.

It is enough to contact us to manufacture high quality polo T-shirts for your brand. Polo T-shirt collar type can be knitted or shirt collar. We can use pique as fabric or dry-touch (called dri-fit) as technical fabric. We will always be at your side as Conbello Textile when you ask for advice on fabric blends and other technical issues. We can embroider your brand logo for polo shirts.

We will provide information on different embroidery techniques on high quality polo t-shirts for your brand. Embroidery can be applied directly to the fabric, as well as we use high-quality embroidery applications in our production. For example, 3D Embroidery, Patch type embroidery. Also, of course, you don't have to use embroidery just for the brand logo. We especially recommend our high quality brand logo printing systems such as silicone printing and 3D-Flexo that we use in our other sportswear products. When you contact Conbello Textile, we will inform you about all the brand logo application systems we mentioned. The images we will send will provide you with enough information.

For your activewear brand for Golf or Tennis sports, we recommend different fabrics from high quality polyester or cotton fabrics in the manufacture of Polo collar T-shirts. We manufacture with performance fabrics that make the user comfortable by evaporating the sweat on the body quickly, especially during intense sweating, and increase performance significantly. You are free to design Golf and Tennis T-Shirts as you wish. As an example of polo shirt design, we can give shirt collar or knit collar designs. Or, if you wish, we can add a hidden-open stylish zipper. Of course, your preference can be a button-down Polo shirt. Just let us know.

HIGH QUALITY CUSTOM POLO T-SHIRT / SHIRT MANUFACTURER

Discover the meticulous process behind high-performance golf and tennis apparel for elite brands, from advanced fabrics to flawless logo application.

???? Advanced Fabric Selection

Conbello Textile adds value to your brand vision using high-quality and technical fabrics designed for performance:

- 100% Premium Cotton (Mercerized & Compact)

- Viscose and Elastane Blends

- Tencel™ (Lyocell) for softness

- Micro-Polyester (Dry-Fit Technology)

- Modal and Polyamide (Nylon) Blends

???? Premium Branding Techniques

We utilize all advanced printing techniques to produce your polo shirt designs to the highest global standards:

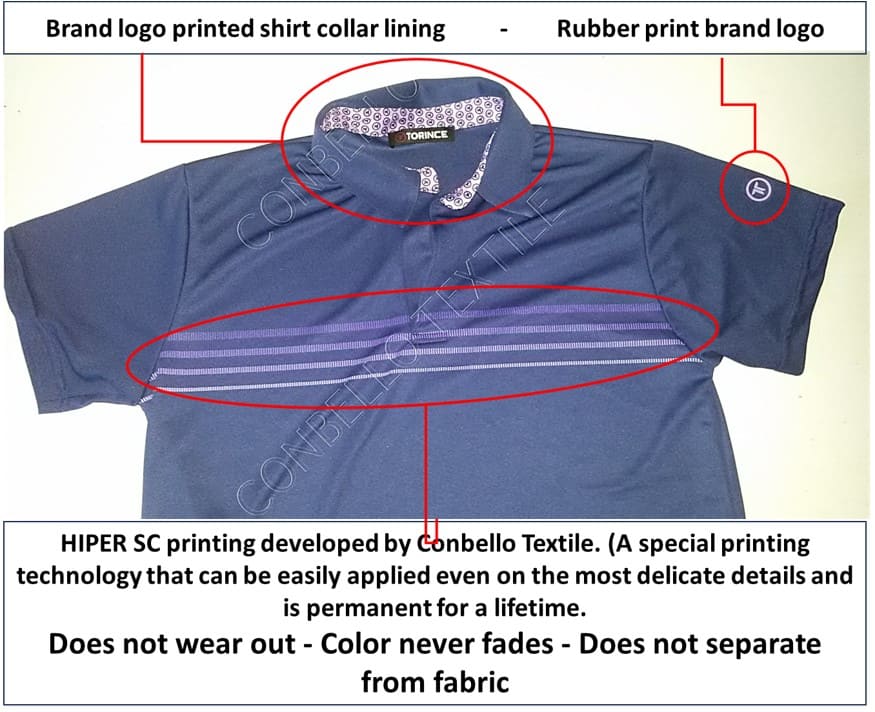

- HYPER SC™: Ultra-premium, non-peeling transfer.

- Embroidery: High-definition thread application.

- Digital Sublimation: For full-body prints.

- DTF Printing: Detailed graphic capabilities.

- Silicone Application: Modern 3D branding.

The High Cost of Cheap Manufacturing:

Why Low-Quality Polos Destroy Brands

If you prioritize "cheapest price" over "high standards" for polo shirts, you are not saving money. You are risking your brand reputation. Here are the hidden technical failures of cheap production:

⚠️ 1. The "First Wash" Nightmare: Fading & Toxins

THE RISK: Cheap manufacturers save money on chemicals. A navy blue polo turns into a dull grey after one wash. Worse, cheap dyeing processes often leave toxic residues on the fabric.

THE CONBELLO STANDARD: We use certified, eco-friendly dyeing processes with high color fastness. Your colors stay vibrant, and your customers remain safe from toxins.

⚠️ 2. Fabric Degradation (The "Pilling" Effect)

THE RISK: Cheap "Open-End" cotton or low-grade polyester fibers break easily. This leads to "pilling" (small fuzzballs) on the collar and underarms after minimal use, destroying the premium feel.

THE CONBELLO STANDARD: We use "Compact Spun" yarns and Bio-Polishing treatments to ensure a smooth, durable surface that resists pilling over time.

⚠️ 3. Serious Shrinkage (The Size Problem)

THE RISK: Unstabilized fabric shrinks drastically. A customer buys a Large polo, washes it once, and it shrinks to a Medium or becomes too short to wear.

THE CONBELLO STANDARD: All our fabrics undergo rigorous pre-shrinkage and stabilization processes. A Large stays a Large, wash after wash.

⚠️ 4. Peeling Logos & Prints

THE RISK: On synthetic polo fabrics, cheap heat transfers adhere poorly. Your carefully designed logo will peel off or crack after a few weeks, making the garment look worthless.

THE CONBELLO STANDARD: Our proprietary HYPER SC™ technology bonds molecularly with the fabric. We guarantee logos that never peel, crack, or fade.

⚠️ 5. Poor Craftsmanship (The Speed Trap)

THE RISK: Cheap production prioritizes speed over quality. This results in loose buttons, unraveling plackets, and low stitch density that bursts under movement.

THE CONBELLO STANDARD: We use high-quality threads and precise stitching protocols. Our polo plackets are reinforced, and buttons are securely attached for durability.

⚠️ 6. Shape Distortion (Twisting)

THE RISK: Cheap polos often suffer from "spirality" (twisting side seams) after washing. The garment loses its symmetry and fits poorly on the body.

THE CONBELLO STANDARD: Our cutting and sewing techniques ensure the garment maintains its structural integrity and silhouette throughout its lifespan.

HIGH QUALITY CUSTOM POLO T-SHIRT / SHIRT MANUFACTURER

Discover the meticulous process behind high-performance golf and tennis apparel for elite brands, from advanced fabrics to flawless logo application.

???? Advanced Fabric Selection

Conbello Textile adds value to your brand vision using high-quality and technical fabrics designed for performance:

- 100% Premium Cotton (Mercerized & Compact)

- Viscose and Elastane Blends

- Tencel™ (Lyocell) for softness

- Micro-Polyester (Dry-Fit Technology)

- Modal and Polyamide (Nylon) Blends

???? Premium Branding Techniques

We utilize all advanced printing techniques to produce your polo shirt designs to the highest global standards:

- HYPER SC™: Ultra-premium, non-peeling transfer.

- Embroidery: High-definition thread application.

- Digital Sublimation: For full-body prints.

- DTF Printing: Detailed graphic capabilities.

- Silicone Application: Modern 3D branding.

The High Cost of Cheap Manufacturing:

Why Low-Quality Polos Destroy Brands

If you prioritize "cheapest price" over "high standards" for polo shirts, you are not saving money. You are risking your brand reputation. Here are the hidden technical failures of cheap production:

⚠️ 1. The "First Wash" Nightmare: Fading & Toxins

THE RISK: Cheap manufacturers save money on chemicals. A navy blue polo turns into a dull grey after one wash. Worse, cheap dyeing processes often leave toxic residues on the fabric.

THE CONBELLO STANDARD: We use certified, eco-friendly dyeing processes with high color fastness. Your colors stay vibrant, and your customers remain safe from toxins.

⚠️ 2. Fabric Degradation (The "Pilling" Effect)

THE RISK: Cheap "Open-End" cotton or low-grade polyester fibers break easily. This leads to "pilling" (small fuzzballs) on the collar and underarms after minimal use, destroying the premium feel.

THE CONBELLO STANDARD: We use "Compact Spun" yarns and Bio-Polishing treatments to ensure a smooth, durable surface that resists pilling over time.

⚠️ 3. Serious Shrinkage (The Size Problem)

THE RISK: Unstabilized fabric shrinks drastically. A customer buys a Large polo, washes it once, and it shrinks to a Medium or becomes too short to wear.

THE CONBELLO STANDARD: All our fabrics undergo rigorous pre-shrinkage and stabilization processes. A Large stays a Large, wash after wash.

⚠️ 4. Peeling Logos & Prints

THE RISK: On synthetic polo fabrics, cheap heat transfers adhere poorly. Your carefully designed logo will peel off or crack after a few weeks, making the garment look worthless.

THE CONBELLO STANDARD: Our proprietary HYPER SC™ technology bonds molecularly with the fabric. We guarantee logos that never peel, crack, or fade.

⚠️ 5. Poor Craftsmanship (The Speed Trap)

THE RISK: Cheap production prioritizes speed over quality. This results in loose buttons, unraveling plackets, and low stitch density that bursts under movement.

THE CONBELLO STANDARD: We use high-quality threads and precise stitching protocols. Our polo plackets are reinforced, and buttons are securely attached for durability.

⚠️ 6. Shape Distortion (Twisting)

THE RISK: Cheap polos often suffer from "spirality" (twisting side seams) after washing. The garment loses its symmetry and fits poorly on the body.

THE CONBELLO STANDARD: Our cutting and sewing techniques ensure the garment maintains its structural integrity and silhouette throughout its lifespan.

![Equestrian Clothing Manufacturer Europe [ Turkey ] Equestrian Clothing Manufacturer Europe [ Turkey ]](image/cache/A PERFORMANS/Equestrian-Clothing-and-Breeches-Manufacturer-200x200.jpg)