Custom Sportswear Manufacturer |Turkey

High Quality Luxury Sportswear Manufacturer

Conbello Textile provides all-in-one service including design, fabric and printing technology in the manufacture of High Quality Luxury Sportswear.

Premium Sportswear Manufacturer [ Istanbul - Türkiye ]

Clothes and Fitness Clothes manufacturer Turkey

As Conbello Textile, we estimate the information that you can easily access when you do research on sportswear manufacturing. Unfortunately, these articles, information, motivational statements, and clothing manufacturers' websites that encourage you to build your sportswear brand do not fully reflect the truth.

You must understand that this vital technical information is vital to the development and growth of your clothing brand. There’s no easy way out If you care about the meaning of what we are talking about for your sportswear brand, we recommend you to continue with the blue text below after reading the short explanation about Conbello Textile.

End-to-end sportswear manufacturing

Conbello Textile has all the certificates, including ISO 9001, ISO 10002 manufactures in Turkey (Istanbul) and produces the designs of its customers' brands in a fully integrated way from end to end. With its 5 factories and 15 departments, it successfully manufactures extremely complex designs as well as standard designs. Conbello Textile not only performs end-to-end production, but also uses its deep technical experience for the sustainable growth and prestige of your brand. It develops and manufactures its own technical fabrics as well as an unlimited variety of high-quality fabrics. Conbello Textile offers a unique, fully integrated end-to-end service with free design support, free tech pack creation and technical advice. We look forward to seeing you in our broad customer network, ranging from start-up companies to global brands and military-technical clothing.

Extreme Sportswear Production

Many are not true fully integrated manufacturers. Most of them are actually offices and/or intermediary firms. For example, a large global company may actually have its sportswear products made by real manufacturers in different countries and present them as if they were made in-house. In fact, the ratio of these companies we mentioned is just above 85%. In this case, you cannot contact the real manufacturer that produces your sportswear designs, and you will not even know the name of the manufacturer. So, is this issue important to you? It is more important than you might think. Not only do you get your sportswear designs more expensive than you think. You cannot expect your designs to be of high quality without working with a real manufacturer, without technical support and advice to ensure your designs are of high quality. In this case, you cannot expect the use of high quality original and real fabrics (Please read our yellow article below if you want to examine this vital technical issue separately). Also, unfortunately, between the sportswear manufacturers and you

You cannot customize your designs as you wish. Of course, if you are thinking of producing cheap and disposable or unsaleable fitness clothing, which we call disposable (promotional) products, you can follow this path.

The vast majority of the rest is the so-called semi-manufacturer. What this means is this. Let's take the T-shirt you customize for your brand. The semi-manufacturer does only one of the final production stages of the T-shirt. For example, just sewing t-shirts. The processes required for the t-shirt to be finalized are outsourced to different companies. We leave the serious problems you will face to your imagination for now.

Conbello Textile is a high-quality luxury sportswear manufacturer based in Turkey, offering complete end-to-end production services. We support global brands and startups with design development, premium fabrics, advanced printing technologies, and flexible manufacturing solutions. We provide a free tech pack for your designs and accept low minimum order quantities, making it easy and cost-effective to launch your custom sportswear line. CONBELLO TEXTILE: ALL-IN-ONE HIGH-QUALITY GARMENT MANUFACTURING

Garment production with low minimum order quantities under the New Brand Support Program.

Specialized sportswear manufacturer.

Design➔Cutting➔Printing➔Sewing➔Packaging➔Global Shipping

⚠️ Industry Reality Check: Fraud & Quality Issues

In the sportswear industry, especially with premium fabrics like Polyester, Polyamide, Bamboo, Cotton, and Tencel, misinformation and fraud are common. Producing high-quality garments at low order volumes (Low MOQ) is challenging, and many manufacturers cut corners.

3 Common Manufacturing Frauds You Must Know:

- 1. Fabric Composition Fraud: A product labeled as "Polyamide" (which is expensive and high-quality) might actually be made of "Polyester" (cheaper). Similarly, so-called "Bamboo" fabrics are often mixed with cheap Viscose or Cotton to reduce costs. At Conbello, we test and verify every roll of fabric.

- 2. GSM (Weight) Deception: If a t-shirt requires 240 gsm fabric, some manufacturers secretly use 200-220 gsm fabric to save money. This results in a thin, cheap-feeling product.

- 3. Missing Finishing Processes: To save time and money, cheap production skips vital steps like Color Fastness and Anti-Pilling treatments. The result? A garment that shrinks, fades, and pills after the first wash.

The Conbello Difference: We apply military-grade inspection protocols. What you order is exactly what you get—no tricks, no hidden substitutions.

???? Challenges for New Brands vs. Conbello Solutions

The biggest hurdle for new brands is the inability to get high-quality manufacturing due to low order volumes. This often forces them to settle for low-quality, generic products.

Conbello Textile's Approach: We believe that even a 100-piece order deserves Global Brand Quality. Whether you are a startup or an established brand, our production quality remains consistently premium.

Why High Quality Matters for Your ROI:

- Durability: Cheap sportswear loses shape and color instantly. High-quality garments last for years, building customer loyalty.

- True Sizing: Cheap fabrics shrink significantly (an 'M' becomes an 'S'). Our pre-shrunk, stabilized fabrics ensure perfect fit over time.

- Cost Efficiency: A "cheap" production run costs you 4-5 times more in the long run due to returns, bad reviews, and lost customers.

✅ Conbello Manufacturing Protocol

Step Protocol Detail Our Promise 1 Raw Material Integrity Real Polyamide, Real Bamboo. Anti-pilling & color-fixing finishes applied as standard. 2 Sewing Quality Reinforced stitching and premium threads suitable for high-intensity athletic movement. 3 Full Transparency Direct communication, no intermediaries, and complete technical guidance. 4 Support Services Free Tech Packs, Logo Design Support, and Customs/Logistics handling included.

CONBELLO TEXTILE: ALL-IN-ONE HIGH-QUALITY GARMENT MANUFACTURING

Garment production with low minimum order quantities under the New Brand Support Program.

Specialized sportswear manufacturer.

⚠️ Industry Reality Check: Fraud & Quality Issues

In the sportswear industry, especially with premium fabrics like Polyester, Polyamide, Bamboo, Cotton, and Tencel, misinformation and fraud are common. Producing high-quality garments at low order volumes (Low MOQ) is challenging, and many manufacturers cut corners.

3 Common Manufacturing Frauds You Must Know:

- 1. Fabric Composition Fraud: A product labeled as "Polyamide" (which is expensive and high-quality) might actually be made of "Polyester" (cheaper). Similarly, so-called "Bamboo" fabrics are often mixed with cheap Viscose or Cotton to reduce costs. At Conbello, we test and verify every roll of fabric.

- 2. GSM (Weight) Deception: If a t-shirt requires 240 gsm fabric, some manufacturers secretly use 200-220 gsm fabric to save money. This results in a thin, cheap-feeling product.

- 3. Missing Finishing Processes: To save time and money, cheap production skips vital steps like Color Fastness and Anti-Pilling treatments. The result? A garment that shrinks, fades, and pills after the first wash.

The Conbello Difference: We apply military-grade inspection protocols. What you order is exactly what you get—no tricks, no hidden substitutions.

???? Challenges for New Brands vs. Conbello Solutions

The biggest hurdle for new brands is the inability to get high-quality manufacturing due to low order volumes. This often forces them to settle for low-quality, generic products.

Conbello Textile's Approach: We believe that even a 100-piece order deserves Global Brand Quality. Whether you are a startup or an established brand, our production quality remains consistently premium.

Why High Quality Matters for Your ROI:

- Durability: Cheap sportswear loses shape and color instantly. High-quality garments last for years, building customer loyalty.

- True Sizing: Cheap fabrics shrink significantly (an 'M' becomes an 'S'). Our pre-shrunk, stabilized fabrics ensure perfect fit over time.

- Cost Efficiency: A "cheap" production run costs you 4-5 times more in the long run due to returns, bad reviews, and lost customers.

✅ Conbello Manufacturing Protocol

| Step | Protocol Detail | Our Promise |

|---|---|---|

| 1 | Raw Material Integrity | Real Polyamide, Real Bamboo. Anti-pilling & color-fixing finishes applied as standard. |

| 2 | Sewing Quality | Reinforced stitching and premium threads suitable for high-intensity athletic movement. |

| 3 | Full Transparency | Direct communication, no intermediaries, and complete technical guidance. |

| 4 | Support Services | Free Tech Packs, Logo Design Support, and Customs/Logistics handling included. |

Conbello Textile is Turkey's leading company engaged in end-to-end fully integrated clothing manufacturing.

You can view our certificates from this link.

Conbello Textile is a luxury sportswear manufacturer in Turkey offering end-to-end service, premium fabrics, free tech pack support, and low MOQ production.

Misleading information and frauds made in all fabrics such as Polyester, Polyamide, Bamboo, Cotton, Tencel, Punto Di Rome etc. used in the manufacture of fitness wear

At low order quantities (low moq) it is particularly difficult to achieve high quality garments. For more information and solutions, please click on this link. Turkey low moq clothing manufacturer

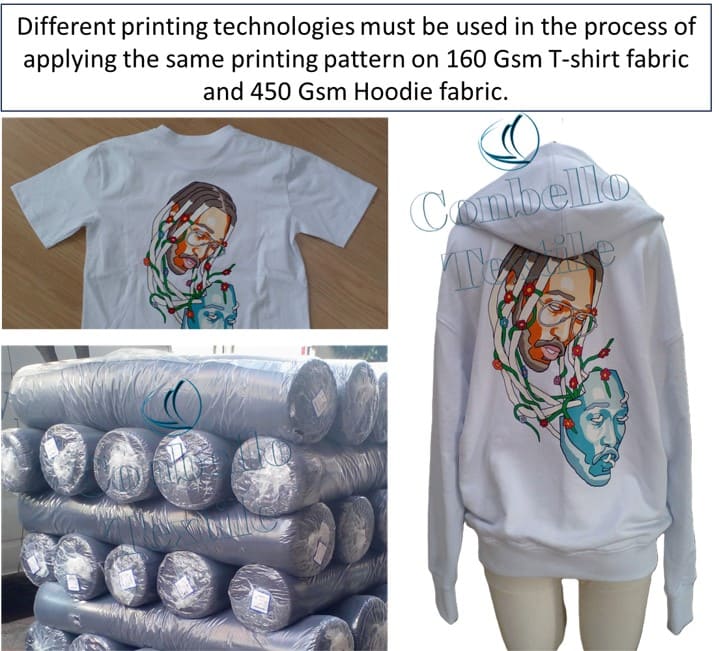

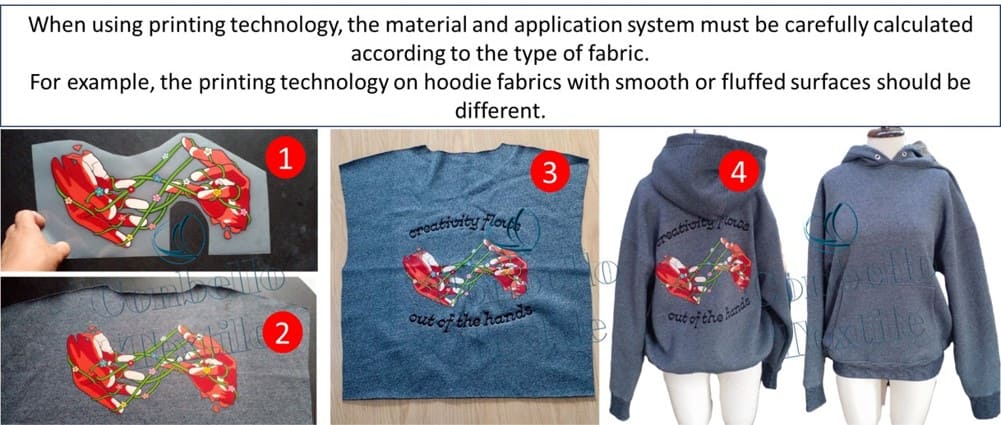

The impact of the production quality of apparel such as hoodies and sweatshirts on your brand

Discover what you're not being told about the gray area involved in making fitness apparel.

The impact of the production quality of apparel such as hoodies and sweatshirts on your brand

Discover what you're not being told about the gray area involved in making fitness apparel.

How To Manufacture Custom Sportswear, Fitness Wear, Street Fashion Clothing And Gym ClothingWe've thought of everything down to the last detail to start or grow your clothing brand. We offer a fully integrated, exceptional end-to-end service, from free design support to top quality original fabrics and delivery to your address with high-end printing systems and craftsmanship.

Please follow the link to get technical information about common mistakes in fitness clothing. Manufacture of high quality technical sportswear

The following are vital factors in the sustainable success of a clothing brand: the manufacturer being a genuine producer (no intermediaries, direct communication with the manufacturer), the manufacturer's design development capabilities, fabric quality, stitching workmanship, print quality, and consistent quality manufacturing and end-to-end shipping services for recurring orders.

How exactly is the production of sportswear tailored to your brand done?

You can also visit our frequently asked questions page on technical issues. If you want more in-depth information, the information on our Tech blog can help.

CONBELLO TEXTILE ADVANCED MANUFACTURING ECOSYSTEM:

TECHNOLOGIES & SOLUTIONS

Defining the Future of Premium Sportswear Production

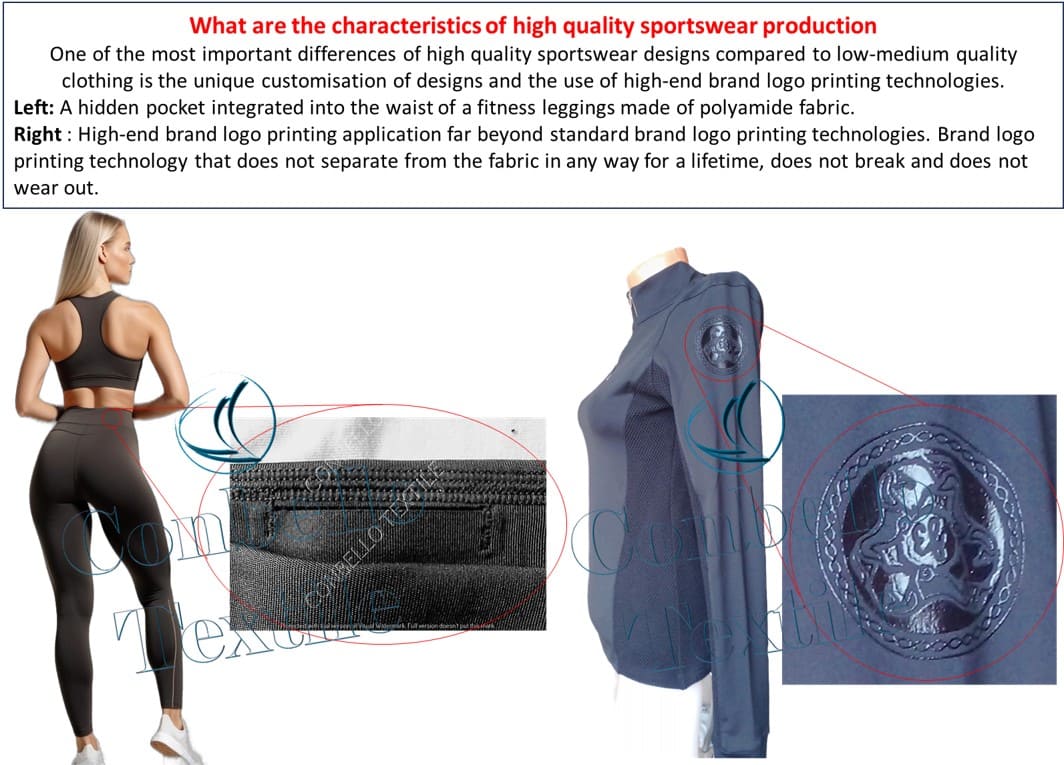

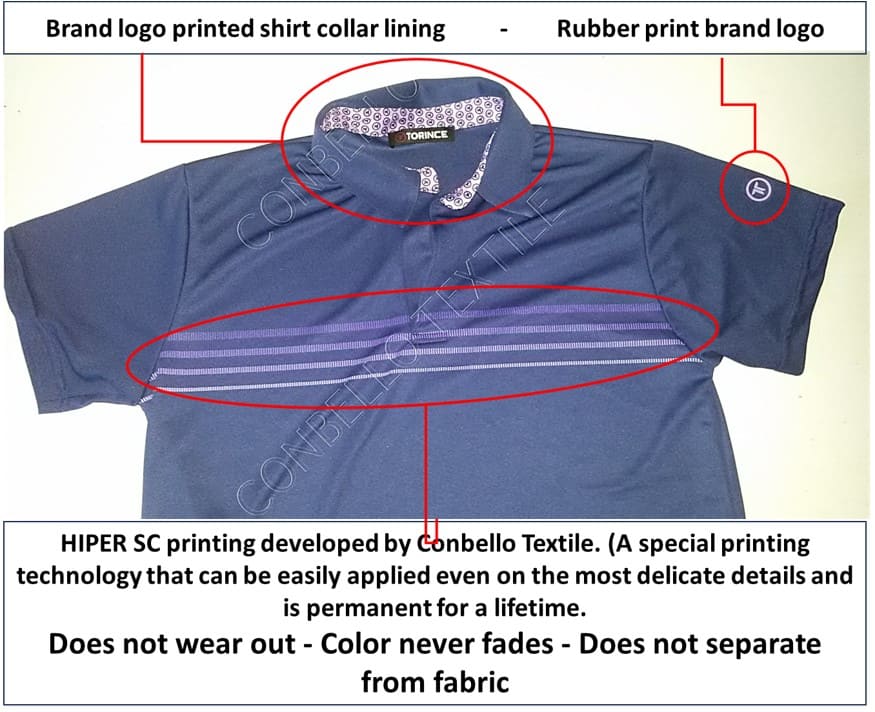

1. HYPER SC™: Unique quality brand logo printing that enhances the value of the garment.

❌ Standard Heat-TransferThe Industry Trap: Most manufacturers use cheap heat-transfer because it is inexpensive and easy to apply. However, for premium brands—especially those using synthetic fabrics—it is a disaster.

Dye Migration Problem: On fabrics like Polyester and Polyamide (Nylon), the fabric dye penetrates the logo over time. This is chemically unavoidable with standard transfers.

The Result: After just a few washes, the logo peels off, cracks, and fades. A peeling logo makes even the most expensive garment look like a cheap, low-quality product.

✅ HYPER SC™ TechnologyDeveloped by Conbello R&D: We developed this proprietary technology specifically because our clients complained about standard logos failing on high-stretch activewear.

Molecular Bonding: Unlike stickers that sit on top, HYPER SC bonds with the fabric fibers at a molecular level.

Lifetime Durability: We guarantee that the logo will never peel, crack, or separate, even under extreme stretching or harsh washing conditions. It lasts as long as the garment itself.

2. The High Cost of "Cheap" Manufacturing

Regardless of your niche—whether yoga leggings, gym wear, or waterproof jackets—the industry rule is absolute: If a garment seems "cheap," it will cost you far more in the long run. If a quote is below market standard, quality is being compromised in critical ways:

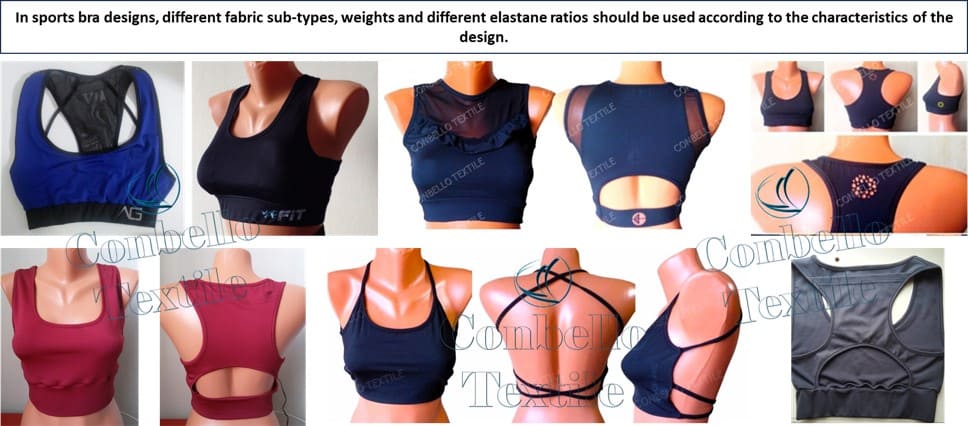

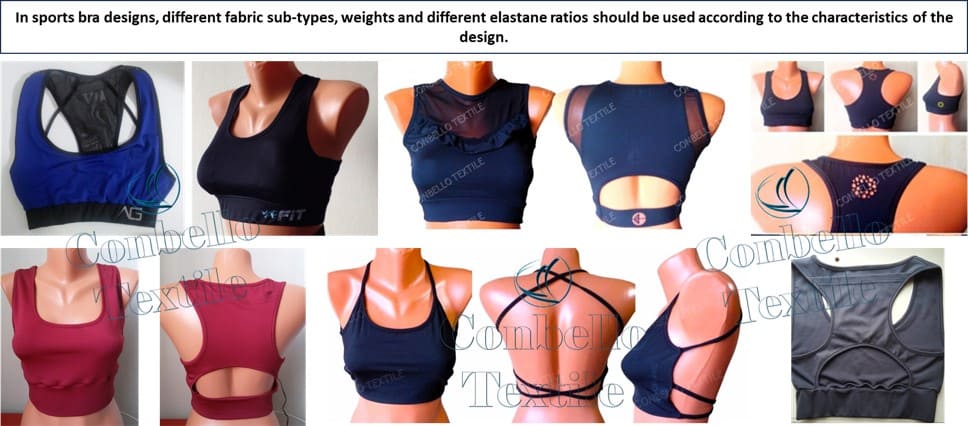

CASE A: Leggings & Sports Bras- Fabric & Form Failure: Cheap Polyester/Polyamide loses its shape instantly. Seams burst because the thread quality cannot withstand athletic movement.

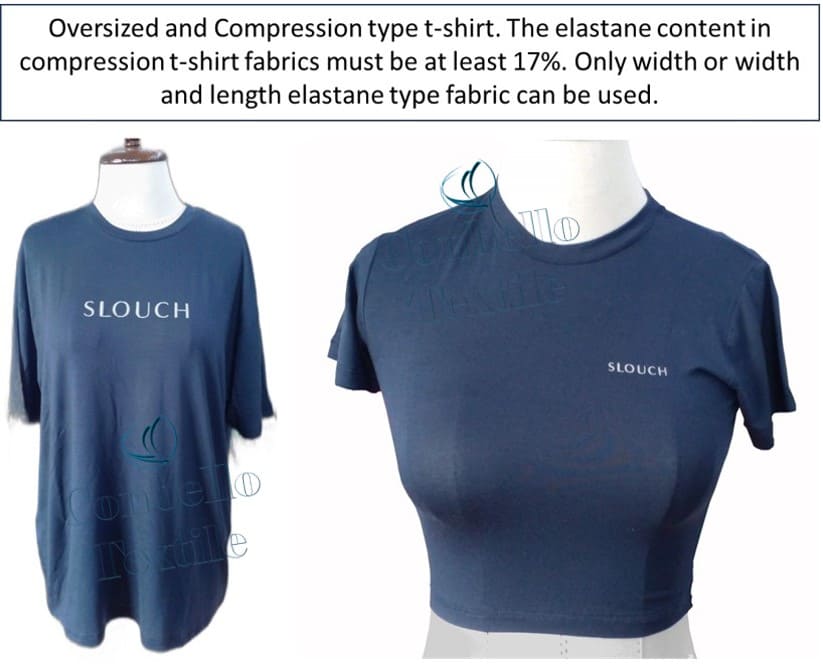

- Weight & Transparency Deception: Manufacturers use low GSM (thinner) fabrics with poor-quality Elastane. The result is a see-through garment that offers no muscle support.

- HEALTH HAZARD (TOXIC DYES): Cheap fabrics are colored with low-grade dyes containing heavy metals. During exercise, your skin's pores open, absorbing these toxic chemicals which can disrupt the Endocrine (Hormonal) System.

- No Functionality: Lacks moisture-wicking properties; it traps sweat and bacteria against the skin, causing odors and irritation.

- Fit & Pattern Errors: Poor workmanship leads to chafing (skin irritation) and designs that do not contour to the body correctly.

CASE B: The "100% Cotton" Trap- The "Open-End" Fraud: They may claim it's "100% Cotton," but cheap manufacturers use "Open-End" cotton. This is often made from waste fabric scraps boiled with resin. It is composed of very short fibers.

- Why Short Fibers Fail: Short fibers break easily, leading to fuzziness (pilling) and holes after minimal use. Real quality comes from Long-Staple Fibers.

- Missing Treatments: To cut costs, they skip essential finishing processes like Color Fastness (anti-fading) and Pre-Shrinkage. Your "Medium" shirt becomes a "Small" after one wash.

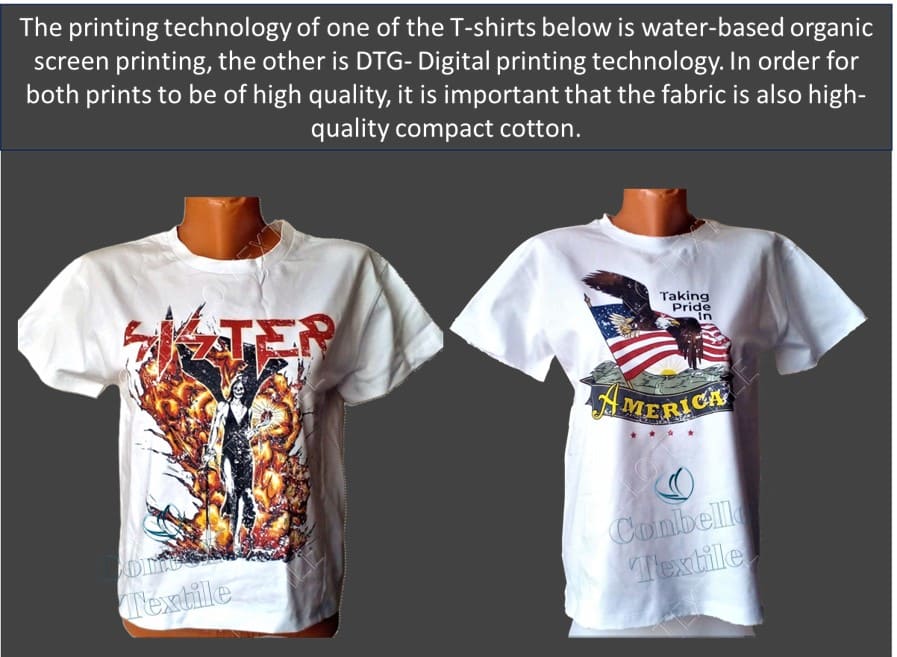

- Conbello Standard: We use only Oeko-Tex certified, Long-Staple Compact Cotton with full stabilization treatments.

3. New Brand Support & Free Tech Packs

Are you a startup or a small business? We listened to your requests. After rigorous testing, Conbello established a Low MOQ Protocol that maintains Global Brand Quality standards for small orders.

A. No Tech Pack? No Problem.We understand that creating a technical file is difficult. Conbello creates professional Tech Packs for FREE as part of our end-to-end service. Simply send us:

- A simple hand sketch of your idea.

- Product photos or mood boards.

- A URL link to a garment you like (for reference).

B. Technical Feasibility & OptimizationEven if you have a Tech Pack, your design might need adjustments for reality:

- Logo Analysis: If your logo has extremely thin lines, it may peel off certain textures. We analyze and optimize the logo design for the specific printing technology.

- Fabric Matching: If your desired technical features (like high compression) don't match your requested fabric, we identify and propose the ideal fabric type and weight (GSM).

We manage the entire process—from design feasibility to global logistics—so you can focus on growing your brand.

CONBELLO TEXTILE ADVANCED MANUFACTURING ECOSYSTEM:

TECHNOLOGIES & SOLUTIONS

Defining the Future of Premium Sportswear Production

1. HYPER SC™: Unique quality brand logo printing that enhances the value of the garment.

The Industry Trap: Most manufacturers use cheap heat-transfer because it is inexpensive and easy to apply. However, for premium brands—especially those using synthetic fabrics—it is a disaster.

Dye Migration Problem: On fabrics like Polyester and Polyamide (Nylon), the fabric dye penetrates the logo over time. This is chemically unavoidable with standard transfers.

The Result: After just a few washes, the logo peels off, cracks, and fades. A peeling logo makes even the most expensive garment look like a cheap, low-quality product.

Developed by Conbello R&D: We developed this proprietary technology specifically because our clients complained about standard logos failing on high-stretch activewear.

Molecular Bonding: Unlike stickers that sit on top, HYPER SC bonds with the fabric fibers at a molecular level.

Lifetime Durability: We guarantee that the logo will never peel, crack, or separate, even under extreme stretching or harsh washing conditions. It lasts as long as the garment itself.

2. The High Cost of "Cheap" Manufacturing

Regardless of your niche—whether yoga leggings, gym wear, or waterproof jackets—the industry rule is absolute: If a garment seems "cheap," it will cost you far more in the long run. If a quote is below market standard, quality is being compromised in critical ways:

- Fabric & Form Failure: Cheap Polyester/Polyamide loses its shape instantly. Seams burst because the thread quality cannot withstand athletic movement.

- Weight & Transparency Deception: Manufacturers use low GSM (thinner) fabrics with poor-quality Elastane. The result is a see-through garment that offers no muscle support.

- HEALTH HAZARD (TOXIC DYES): Cheap fabrics are colored with low-grade dyes containing heavy metals. During exercise, your skin's pores open, absorbing these toxic chemicals which can disrupt the Endocrine (Hormonal) System.

- No Functionality: Lacks moisture-wicking properties; it traps sweat and bacteria against the skin, causing odors and irritation.

- Fit & Pattern Errors: Poor workmanship leads to chafing (skin irritation) and designs that do not contour to the body correctly.

- The "Open-End" Fraud: They may claim it's "100% Cotton," but cheap manufacturers use "Open-End" cotton. This is often made from waste fabric scraps boiled with resin. It is composed of very short fibers.

- Why Short Fibers Fail: Short fibers break easily, leading to fuzziness (pilling) and holes after minimal use. Real quality comes from Long-Staple Fibers.

- Missing Treatments: To cut costs, they skip essential finishing processes like Color Fastness (anti-fading) and Pre-Shrinkage. Your "Medium" shirt becomes a "Small" after one wash.

- Conbello Standard: We use only Oeko-Tex certified, Long-Staple Compact Cotton with full stabilization treatments.

3. New Brand Support & Free Tech Packs

Are you a startup or a small business? We listened to your requests. After rigorous testing, Conbello established a Low MOQ Protocol that maintains Global Brand Quality standards for small orders.

We understand that creating a technical file is difficult. Conbello creates professional Tech Packs for FREE as part of our end-to-end service. Simply send us:

- A simple hand sketch of your idea.

- Product photos or mood boards.

- A URL link to a garment you like (for reference).

Even if you have a Tech Pack, your design might need adjustments for reality:

- Logo Analysis: If your logo has extremely thin lines, it may peel off certain textures. We analyze and optimize the logo design for the specific printing technology.

- Fabric Matching: If your desired technical features (like high compression) don't match your requested fabric, we identify and propose the ideal fabric type and weight (GSM).

We manage the entire process—from design feasibility to global logistics—so you can focus on growing your brand.

-Sports-Gym-bra-manufacturer.jpg)

![Private Label T-Shirt Manufacturer [ Cotton-Polyester Fabric ] Private Label T-Shirt Manufacturer [ Cotton-Polyester Fabric ]](image/cache/A YENİ EKLENEN ÜRÜN/custom-t-shirt-manufacturer-200x200.jpg)

![Custom Clothing Manufacturer [ Europe-Turkey ] Custom Clothing Manufacturer [ Europe-Turkey ]](image/cache/A YENİ EKLENEN ÜRÜN/fitness-clothing-manufacturer-200x200.jpg)

![Sweat activated Shirt Manufacturer [ Turkey ] Sweat activated Shirt Manufacturer [ Turkey ]](image/cache/A YENİ EKLENEN ÜRÜN/custom-water-sweat-activated-shirt-200x200.jpg)

![Best quality hoodie manufacturer [ Luxury-High Quality ] Best quality hoodie manufacturer [ Luxury-High Quality ]](image/cache/A PERFORMANS/CROP HOODIE-200x200.jpg)

-200x200.jpg)