How to Start a Fitness Clothing Line

How to Start a Fitness Clothing Line

Custom women's sportswear manufacturer

The sportswear market is expected to reach $635 billion by 2028.

According to very comprehensive analysis on a global scale, an increasing number of individuals are adopting health-oriented lifestyles. The global sportswear market was valued at USD 425.37 billion in 2022 and is expected to reach USD 635.69 billion by 2028, growing at a CAGR. Finally, with the end of the threat of the global epidemic and the effect of being freed from psychological pressure, there was an explosion in the sportswear industry faster than before. And sales of fitness clothing continue to increase on a global scale.

Increasing participation of athletes in sports activities, awareness of fitness & wellness, and athleisure trends all contribute to the adoption of sportswear awareness, spending capacity, fitness and healthy lifestyle trends, and evolving fashion preferences.

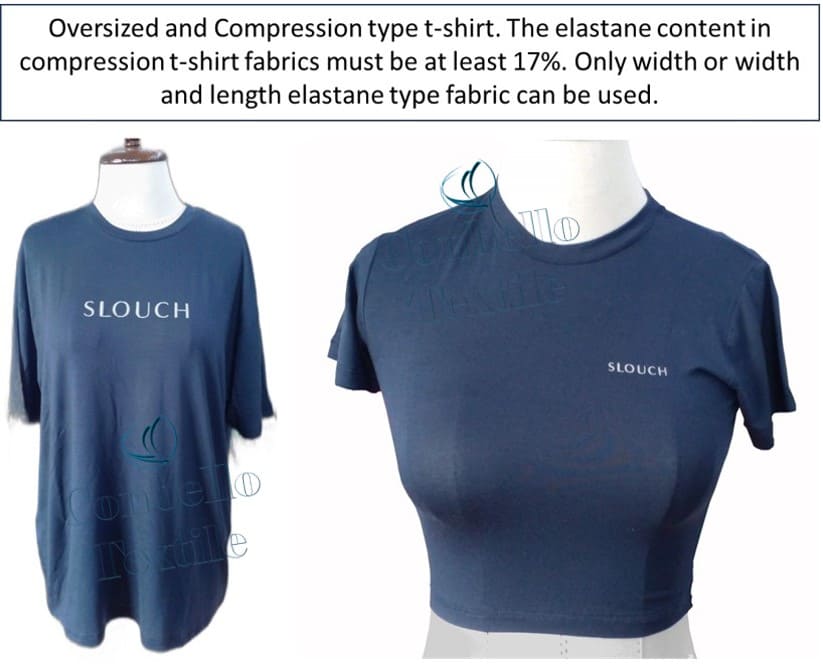

Sportswear encompasses a range of clothing and accessories specifically designed for various sports and physical activities to enhance performance and provide comfort to athletes and fitness enthusiasts. This includes jerseys, shorts, t-shirts, tights, shoes, socks, hats, and more. These garments are engineered to regulate body temperature, making them ideal for athletic pursuits.

Yes, it is a fact that sportswear fashion is on the rise all over the world. Forbes gives detailed information about this. However, synthetic fabrics such as polyester and especially polyamide used in sportswear are proving to be extremely harmful to human health. CNN's Parija Kavilanz does her duty to warn by presenting her information on the subject in a clear and concise manner. Conbello Textile produces fitness clothes without chemical poisons.

For more details about the new generation fabrics used by Conbello Textile in high-quality sportswear, visit here.

Although the most commonly used fabrics in sportswear are mainstream fabrics such as cotton, polyester and polyamide, we see that high-end fabrics such as viscose, tencel and modal are becoming increasingly popular. However, of course, as important as the type of fabric, or even more important, is how the fabric used is produced.

What are the real secrets to sustained success in the fitness apparel business?

The global fitness clothing market is growing rapidly. Both clothing brands and fitness clothing manufacturers are trying to grab a share of this market. Of course, this is a very natural action. New fitness clothing brands and new manufacturers enter the sportswear industry almost every day. This is exactly the point where the sportswear industry has the most difficulty. Every manufacturer who wants to grab a share of the sportswear industry and has no experience in manufacturing fitness clothing or does not have the necessary machinery has started to enter this business. For example, a company that produces men's suits or even a manufacturer that produces tracksuits can enter the fitness clothing manufacturing business. However, these are completely different niche clothing areas. Meanwhile, it is a fact that high-quality sportswear cannot be produced and a high-level service cannot be received by using companies that do not have any technical knowledge and connect manufacturers and brands in return for commission (B2B companies, intermediaries, and offices). As a result, you should work with a fully integrated manufacturer. If you do not have at least 15 years of continuous field experience and technical experience in the fitness clothing industry, this is the only and guaranteed way to be successful.

The inexperience of fitness clothing brands and their approach solely focused on obtaining cheap clothing is, of course, an undeniable fact in diagnosing this problem. Consequently, poor-quality fitness clothing manufacturers will exploit this and cause serious harm.

We can give many examples on this subject. For example, yoga leggings often use polyester or polyamide fabric. (In fact, cotton fabrics, which are extremely healthful, are not very popular lately. In fact, cotton fabric is the only type of fabric that does not contain the toxic BPA chemical substance.)

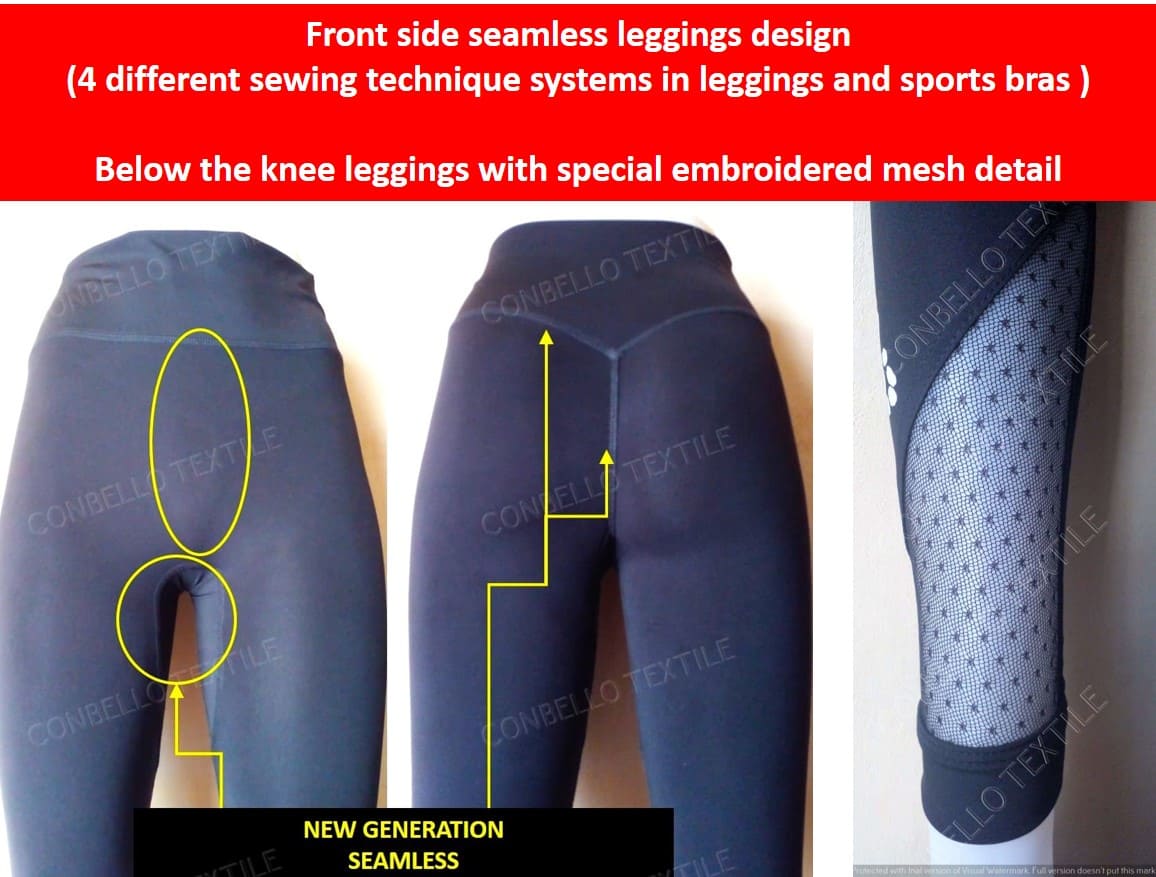

Apart from this, the only aim of a company that produces cheap but poor quality leggings is to produce as much quantity as possible. Therefore, it means that it will not use the special sewing system required for yoga leggings (you can consider this for all other sportswear as well) and will apply sloppy and poor quality sewing. Manufacturing true custom fitness clothing is another highly complex and misunderstood technical subject. For example, the system in which the logo of the brand that placed the production order is simply applied to sportswear clothes, which have already been designed in advance and are mass-produced, is not custom manufacturing. This is called promotional (disposable) production.

At this point, fitness clothing brands fall into the traps of companies that manufacture cheap and therefore low-quality fitness clothing (and have insufficient experience). The main reason for this is that all polyester fabrics are thought to be the same. However, polyester fabrics are divided into many segments based on yarn type, fabric production system, and dyeing type. When a fitness clothing brand orders leggings to be manufactured, it can feel comfortable thinking that the fabric is polyester. However, the damage caused by the manufacturer who uses the poorest quality polyester fabric type to get the manufacturing job has a serious and great danger that will lead to the closure of the brand.

Women's custom sportswear manufacturer

Conbello Textile serves as a school, far beyond being a fully integrated end-to-end sportswear manufacturer. You can find a lot of vital information on this subject on our other pages. For example, like this page of ours. What you're not told in the fitness clothing business. Is gym wear a good business?

Fitness Apparel Manufacturing Guide

How to Start a Fitness Clothing Line

Crafting premium, private-label apparel that defines your brand.

Step-by-Step Guide

If you already have a complete tech pack, you can send it to us directly via email. Alternatively, we offer to create your tech packs for your garments free of charge upon request.

- Define Your Niche: Identify your target audience and the type of fitness apparel you want to create (e.g., yoga, running, weightlifting).

- Develop Your Brand: Create a unique brand identity, including your logo, brand name, and mission statement.

- Design Your Collection: Focus on designs that are both functional and stylish. Consider performance fabrics like polyester and nylon blends.

- Find a Reliable Manufacturer: Partner with a manufacturer like Conbello Textile that offers low MOQ (Minimum Order Quantity), high-quality production, and expertise in performance fabrics.

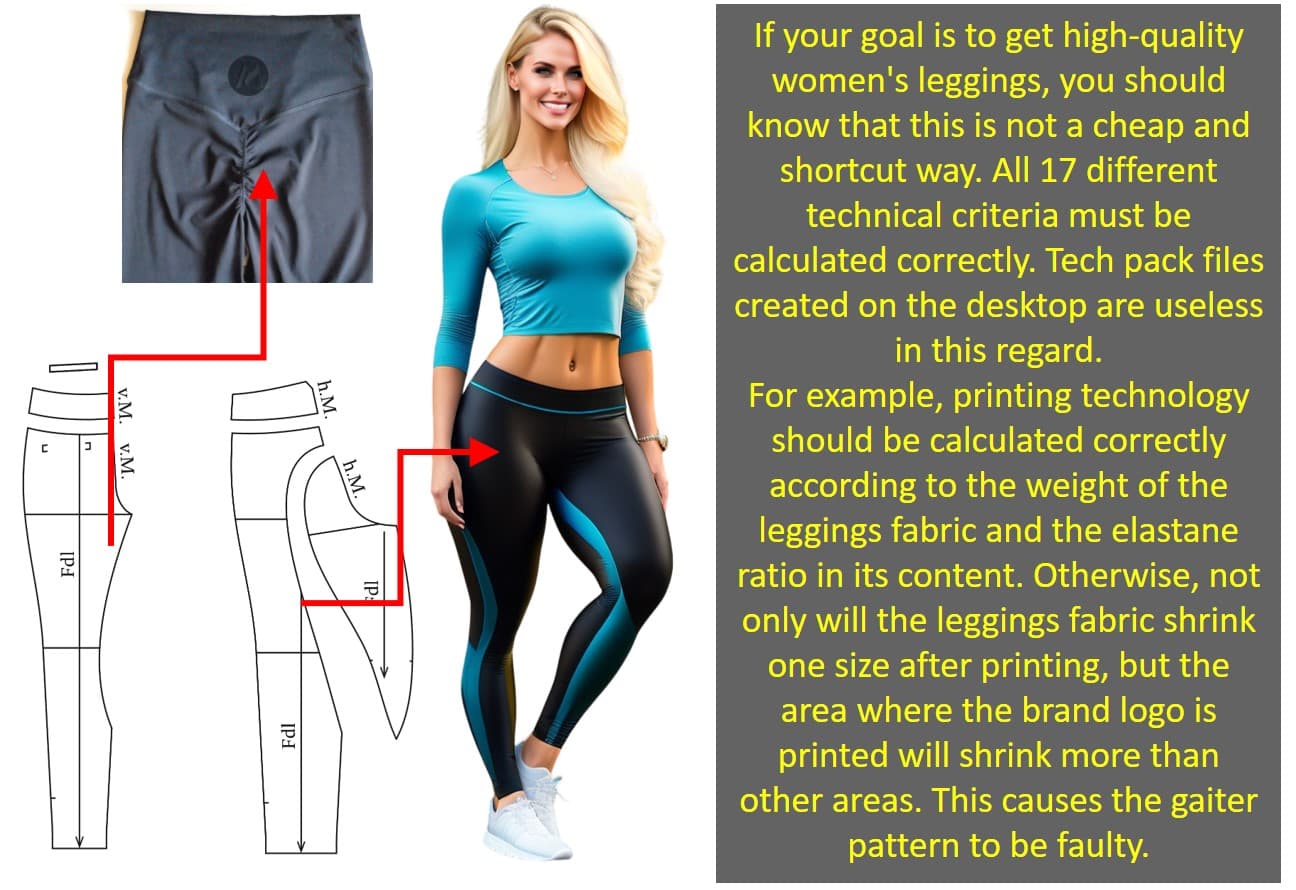

- Create a Tech Pack: Prepare a detailed tech pack that includes all design specifications, measurements, and materials.

- Market and Launch: Develop a marketing strategy to promote your brand and launch your products.

Our R&D team continuously works to create innovative and unique fabrics. We are proud to offer a diverse range of fabrics, including 100% cotton, cotton-polyester blends, polyamide, Tencel, and Bamboo.

We provide full-service support from design to delivery, handling all aspects of production, including sourcing, manufacturing, and logistics. Our team ensures that your finished products are delivered to your doorstep, ready for sale.

Frequently Asked Questions

What fabrics do you use for fitness apparel?

We specialize in premium performance fabrics like moisture-wicking polyester and nylon blends, along with natural materials like Tencel and bamboo, to ensure comfort, durability, and a perfect fit for all types of workouts.

What is the minimum order quantity (MOQ)?

We work with brands of all sizes, from startups to large enterprises. We are committed to providing a low MOQ to help new brands get started without significant upfront investment. We also offer full-scale production for established brands.

Do you handle international shipping?

Yes, we manage all transportation and paperwork, including customs duties, to provide a seamless, door-to-door delivery service for our clients worldwide.

At Conbello Textile, you are assigned a dedicated technician who will be with you at every step of the manufacturing of your sportswear designs.

You are accompanied by a dedicated senior technician to provide comprehensive information, detect possible errors in advance, and closely monitor your production process. Our senior technicians, defined specifically for your brand, have at least 15 years of experience. In addition, we ensure flawless manufacturing of your fitness clothing designs with simultaneous coordination with the relevant departments regarding the technical details.

Please note that this is crucial. For example, we will notify you of any technical issues, such as which printing system is most suitable for your brand logo or if there are any errors in the logo and how to fix them. Alternatively, we will advise you on which sewing technique to use, which will vary depending on your fabric type and the intended use of the design. The outcome will be a sports apparel design that is flawless in every way.

Conbello Textile manufacturing protocol covers all stages of high-end fitness clothing manufacturing, starting from design to wholesale manufacturing.

1-Analysis of fitness clothing designs.

2-Deciding on the fabric to be used in fitness clothing. Making the most suitable selection from unlimited fabric types such as Cotton, Polyester, Polyamide, Viscose, Bamboo.

3-Deciding on the brand logo printing system to be used on the fitness clothing. Deciding on the most suitable one among unlimited printing techniques such as screen printing, transfer, sublimation, and silicone printing.

4 - After making the necessary improvements in the design, deciding on the accessories to be used, and deciding on the printing system, the first prototype outfit is manufactured and sent to the customer's address.

5 - Making revisions, if necessary after the first prototype suit is produced. 6- After all revisions are made in the design, produce the updated final sample suit before wholesale manufacturing.

7- Start wholesale manufacturing after all checks are made and the final decision is made.

8- Send the wholesale production of fitness clothes to the address of the customer anywhere in the world.

How to Start a Fitness Clothing Line

Crafting premium, private-label apparel that defines your brand.

Step-by-Step Guide

If you already have a complete tech pack, you can send it to us directly via email. Alternatively, we offer to create your tech packs for your garments free of charge upon request.

- Define Your Niche: Identify your target audience and the type of fitness apparel you want to create (e.g., yoga, running, weightlifting).

- Develop Your Brand: Create a unique brand identity, including your logo, brand name, and mission statement.

- Design Your Collection: Focus on designs that are both functional and stylish. Consider performance fabrics like polyester and nylon blends.

- Find a Reliable Manufacturer: Partner with a manufacturer like Conbello Textile that offers low MOQ (Minimum Order Quantity), high-quality production, and expertise in performance fabrics.

- Create a Tech Pack: Prepare a detailed tech pack that includes all design specifications, measurements, and materials.

- Market and Launch: Develop a marketing strategy to promote your brand and launch your products.

Our R&D team continuously works to create innovative and unique fabrics. We are proud to offer a diverse range of fabrics, including 100% cotton, cotton-polyester blends, polyamide, Tencel, and Bamboo.

We provide full-service support from design to delivery, handling all aspects of production, including sourcing, manufacturing, and logistics. Our team ensures that your finished products are delivered to your doorstep, ready for sale.

Frequently Asked Questions

What fabrics do you use for fitness apparel?

We specialize in premium performance fabrics like moisture-wicking polyester and nylon blends, along with natural materials like Tencel and bamboo, to ensure comfort, durability, and a perfect fit for all types of workouts.

What is the minimum order quantity (MOQ)?

We work with brands of all sizes, from startups to large enterprises. We are committed to providing a low MOQ to help new brands get started without significant upfront investment. We also offer full-scale production for established brands.

Do you handle international shipping?

Yes, we manage all transportation and paperwork, including customs duties, to provide a seamless, door-to-door delivery service for our clients worldwide.

![Equestrian Clothing Manufacturer Europe [ Turkey ] Equestrian Clothing Manufacturer Europe [ Turkey ]](image/cache/A PERFORMANS/Equestrian-Clothing-and-Breeches-Manufacturer-200x200.jpg)

-200x200.jpg)

![Custom Hoodie Manufacturer [ Türkiye ] Custom Hoodie Manufacturer [ Türkiye ]](image/cache/A YENİ EKLENEN ÜRÜN/HEAVYWEIGHT_1-200x200.jpg)