How to find clothing manufacturer in Turkey ?

'' In most countries around the world, you can find any manufacturer to make any garment. However, there are far fewer truly fully integrated garment manufacturers that can provide impeccable service with high quality manufacturing from start to finish.''

In the field of fashion, producing high-quality clothing is a complex process that requires meticulous attention to detail and adherence to industry standards. This does not apply to a low-quality garment, but actually manufacturing a high-quality garment design is a much more complex process than one might think. From the initial design concept to the final production stage, every step plays a vital role in creating clothing that represents style, comfort, and durability for both men and women. This article will touch on the stages of producing high-quality clothing and will also shed light on technical issues that need to be carefully considered. We will also tell you what we have seen in over 40 years as Conbello Textile. We will also examine the harmful consequences that occur when inexperienced producers overlook these critical aspects.

'' We often see that small and medium-sized clothing brands, who dream of growing, are frustrated because they do not know what is going on in the grey background of clothing manufacturing, even though they have these exciting and beautiful thoughts.

So, to grow a clothing brand, choose your design - find the manufacturer - even find the manufacturer that offers the cheapest price - place your order - and establish or grow your brand. Is this process that easy? Definitely not. ''

Everyone is aware that in today's world, there is not as much time spent reading and acquiring information as before. The great commander Timur said, "A nail saves a shoe, a shoe saves a horse, a horse saves a commander, a commander saves an army, an army saves a country." But what might this statement of this great statesman and commander have to do with clothing manufacturing? Yes, you already understand, but let's explain briefly anyway.

How to find a manufacturer for clothing. Whether it is a seed ready to blossom as a startup brand or a 20-year-old national clothing brand, this is the question they all ask themselves.

''The smallest, insignificant or overlooked mistake in clothing manufacturing will cause the clothing to become rubbish. ''

We can adapt the above quote of the great commander Timur to thousands of examples in clothing manufacturing. Let's give just a few examples. During the sewing of a garment containing a high percentage of elastane in its fabric, if the needle stitching steps and frequency of the sewing machine are not adjusted exactly correctly, the seams of the garment will break after a short use. Or if you fall into the low price trap, the manufacturer will use cheap and poor quality fabric. As a result, in the first wash, the fabric color of the garment will fade, its size will shrink, and since the fabric is not durable, the stitches will not be able to hold and the garment will become unusable.

Experience in clothing manufacturing is much more important than one might think. For example, if a high-quality fabric with a high elastane content is used, the seams will burst in a short time if the sewing technique is not selected according to the technical specifications of the fabric.

In the Conbello Textile manufacturing protocol, we use different fabrics for use inside the gym, for use outside the gym, or high-end technical fabrics for both purposes. We also use different fabrics and sewing techniques in yoga and walking tights. Ultimately, we make a decision by analyzing in detail the fabric, sewing technique-thread and brand logo (or pattern) printing technique required by the design of the outfit.

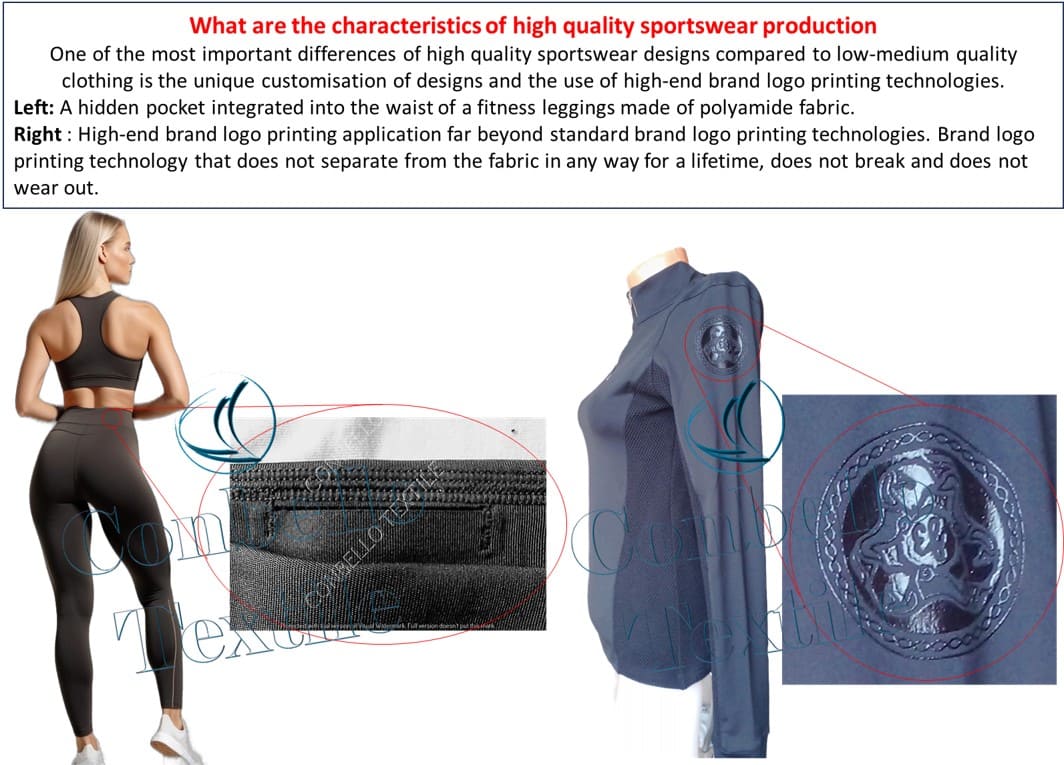

When it comes to high-quality clothing manufacturing, fabric selection, precision of sewing technique and print quality are the difference between success and failure.

Additionally, when you send your brand logo to us, we also check its suitability for printing technology. Not every brand logo may be suitable for every printing system. Otherwise, the brand logo may separate from the fabric surface during the first washes or after a short use.e required by the outfit's design through a thorough analysis.

There is no shortcut to the production of high-quality clothing. The use of low-quality fabric in order to produce clothes more cheaply will give results that ruin a garment such as pilling, discolouration and shrinkage after a short period of use.

Damages caused by inexperienced manufacturers

Inexperienced manufacturers often overlook critical technical aspects, which lead to many harmful consequences: This is the obvious reason. But the reason for this is the low price paid for the production of the garment. As Conbello Textile, we call this the low price trap.

Poor quality: Garments produced by inexperienced manufacturers may show substandard stitching, uneven edges and fabric defects, compromising the overall quality.

Fit issues: Improper grading and fitting can result in garments not fitting properly, which can lead to customer dissatisfaction and increased returns.

Waste: Inefficient fabric processing techniques and lack of precision in cutting can lead to unnecessary waste, increased production costs and harm to the environment.

Reputational Damage: Inconsistent quality and fit can damage a brand's reputation, resulting in customer loss and reduced market presence.

Stages of high-quality clothing production. It involves a meticulous process that includes design, fabric selection, pattern-making, sample development, production, and quality control. Technical aspects play a vital role in ensuring the durability, fit and overall quality of garments. Inexperienced manufacturers will try to produce substandard products that damage their reputation and leave customers dissatisfied because they know they cannot produce a high-quality garment anyway with the manufacturing price they offer.

The design of your garments will be completely bespoke to your brand. We do not produce promotional clothing that is pre-designed and mass-produced as a template. In the Conbello Textile manufacturing protocol, all the components you can think of are specific to your brand. This includes the colour of the zip fabric and the zip handles...

Template production : This is the production made by printing different brand logos on mass-produced garments. However, this production system is not special production, but promotional type production.

The only limit to clothing designs is your imagination. Your dream could be a unique sheer PVU jacket or sports bra. We produce down to the smallest detail only for your brand.

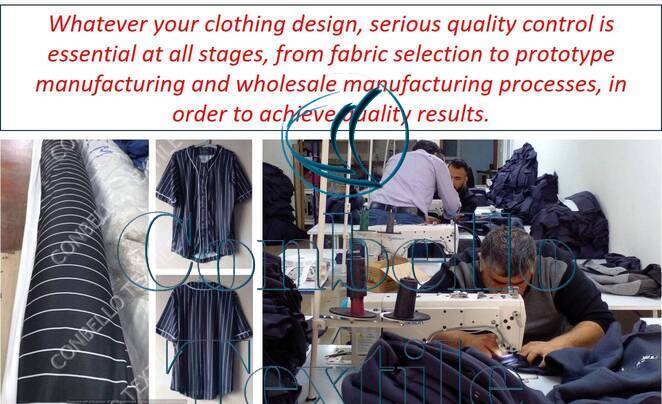

Whatever your garment design, serious quality control is essential at all stages, from fabric selection to prototype production and wholesale production processes, to achieve quality results.

Conbello Textile program for Quality Custom Production Manufacturing:

Custom Clothing Production Method: While the style of the garment is important, the chosen production process has a significant impact on the final quality. This includes factors such as skilled workmanship, attention to detail and the use of appropriate machinery. However, the use of high-tech machinery is not enough. Since the most advanced machine is ultimately operated by a human being, Conbello Textile employs specialised personnel with deep experience in the industry.

Quality Control: Conbello Textile implements rigorous quality control procedures at every stage of production and this helps to detect and correct any faults before the garment reaches the customer. This ensures consistent quality and a well-finished product.

Design Clarity: Conbello Textile has modelers and garment pattern makers with a wealth of experience. If, for example, the post-print shrinkage allowance of the fabric to be used in the pattern drawing and garment design is not calculated correctly, the overall garment pattern will be incorrect. Detailed technical drawings and specifications should leave no room for misinterpretation.

Mould Precision: A perfectly crafted pattern is the foundation of a well-fitting garment. Conbello Textile's skilled pattern makers and modellers meticulously translate the design into a two-dimensional plan, ensuring correct proportions and seam allowances.

Fabric selection: Choosing the right fabric type, subtype and weight is very important in terms of both aesthetics and functionality. For example, the intended uses of fitness and walking leggings are actually very different. Fabric with a higher elastane rate should be used in the production of fitness leggings and a lower elastane rate in the production of walking leggings. However, unfortunately, as Conbello Textile, we find that the clothes produced by different manufacturers in different countries that our customers send us for testing are not actually produced from the fabric listed on the product label. For example, when we analyze the fabric that is stated to stretch in 4-directions and contains 20% elastane, we unfortunately find that it stretches in 2-directions and contains only 10% elastane. Another fabric misleading information that we frequently find is the type and weight of the fabric. For example, a garment labelled as polyester fabric may in fact be low quality unfinished polyester-viscose. This type of fabric will pilling in a very short time and the colour will fade in the first wash. In addition, since it is a fabric that is not pre-wash finished, it will shrink one size after washing. We also frequently detect misleading labelling information on fabric weights. Such as a leggings that is said to be produced as 240 Gsm is actually 200 Gsm.

This fabric misrepresentation can be attributed to two factors. Firstly, some sportswear brands lack the deep technical knowledge to identify these discrepancies. Secondly, some manufacturers may be deliberately exploiting this lack of expertise, or, at best, simply lack the necessary experience themselves.

Considering factors relevant to the garment's intended use, such as drape, breathability or compression effect, helps select the fabric that best suits the design. While technology plays a crucial role in modern garment production, achieving the perfect balance of aesthetics, functionality, and technical specifications ultimately relies on the expertise of experienced professionals.

Sewing System Expertise: A well-considered sewing system goes beyond just choosing a stitch. It involves selecting the appropriate sewing technique, needle type, and thread weight based on the fabric characteristics and desired seam finish. Expertise in these areas ensures strong, durable, and visually appealing seams.

For this reason, although experienced craftsmen work on the Conbello Textile sewing production line, we also have controllers who constantly circulate between the sewing tables and inspect the quality of the completed products.

Thread Compatibility: Sewing thread compatibility with the chosen fabric is essential for optimal performance. For example, using a lightweight thread on a heavy fabric could lead to breakage, while a thick thread on a delicate fabric might cause puckering.

Shoddy seamwork can significantly degrade the quality of any garment, including a simple T-shirt or a detailed ankle-length legging with pockets. This can manifest in various ways, such as excessively tight or loose stitching.

Consequences of Excessively Tight Stitching:

Distorts the fabric's natural shape by bunching it up, restricting the garment's range of motion.

Increases the risk of tearing or bursting due to fabric strain.

Creates an aesthetically unappealing appearance.

Consequences of Excessively Loose Stitching:

Causes the fabric to hang loosely, compromising the garment's shape.

Leads to seam opening or tearing.

Projects an image of weakness and fragility.

Benefits of Proper Seamwork:

Preserves the fabric's natural shape, ensuring a comfortable fit.

Enhances the garment's durability and lifespan.

Imparts a visually pleasing and professional look.

Conbello Textile is the ultimate solution in high quality clothing manufacturing protocol:

Proper seamwork is paramount to the quality of any garment. Substandard seamwork in items like T-shirts and detailed ankle-length leggings with pockets can not only detract from their aesthetic appeal but also substantially reduce their durability and lifespan.

Printing Technique Alignment: The printing method chosen for the brand logo should be appropriate for both the fabric characteristics and the desired aesthetic. Heat transfer, direct-to-garment printing, and embroidery are just a few examples, each with its own advantages and limitations in terms of durability, color vibrancy, and suitability for specific fabrics. We hope that it will be useful to remind you that we use environmentally friendly and chemically toxic-free inks and materials in the printing technologies we use on clothes.