What is the best fabric for fitness wear and sportswear

Common misconceptions about the fabrics used in fitness clothing

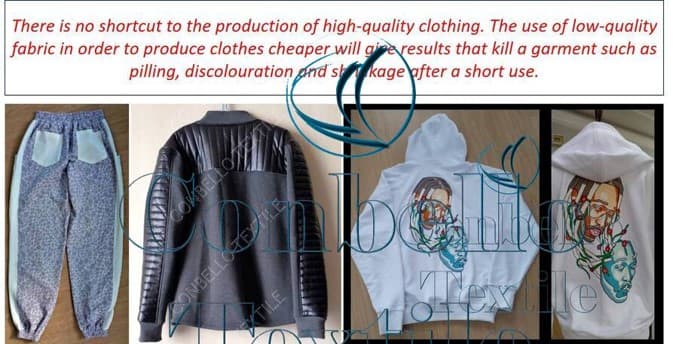

Fabric selection in sportswear is a very sensitive issue, and it is very important which fabric type and weight will be used in which product. The most serious mistake we see in start-up or mid-size sportswear brands is that they only focus on cheap prices. Although it is not a very nice term, it should not be forgotten that free cheese can only be found in a mousetrap. Of course, this issue does not only end with your choice of fabric. You should know much more important and vital technical information about the fabric to be used. !

As Napoleon said, if there is no gunpowder (you can think of it as ammo) there is no point in continuing the war. If you take active wear and sportswear seriously and want to be a permanent and growing brand, you have to know that one of your most important arsenals is fabric.

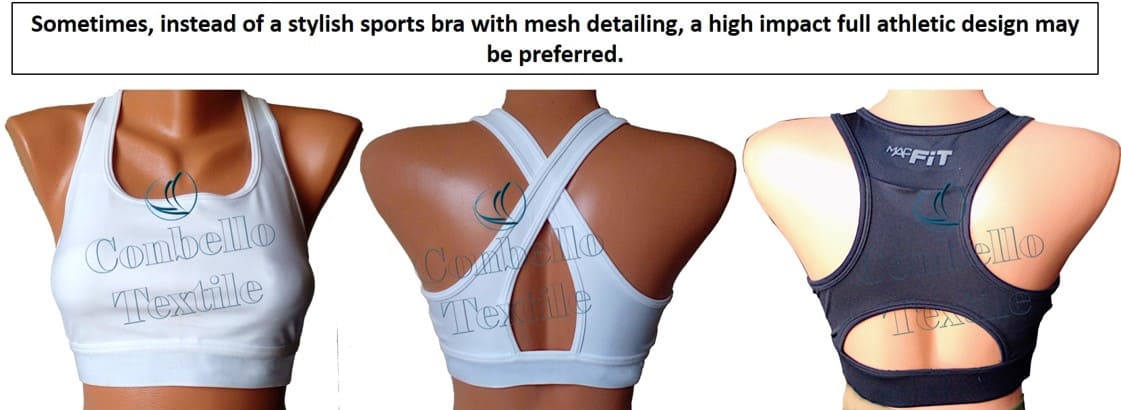

We tried to briefly summarize the points that should be considered in the selection of fabrics to be used in products such as T-shirts, Athletes, Hoodies, Polos, Leggings or Sports Bras as sportswear.

Fabric touch and knitting/weaving systems are also crucial to the excellent quality of your sportswear product.

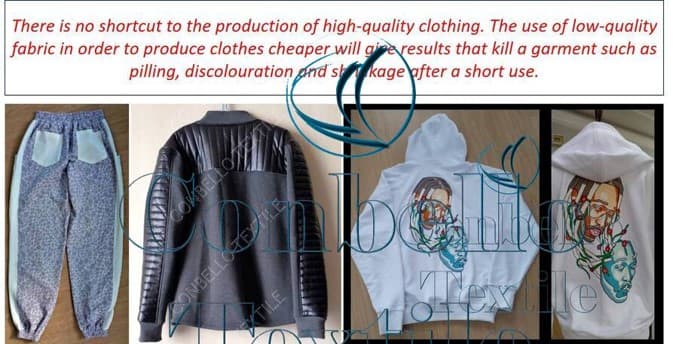

Your fabric should definitely not fade after washing. For this, a special color fixation application is made during the manufacture of the fabric. Much cheaper clothing products can be produced using poor quality fabrics. However, your cheap sportswear products are such a sensitive issue that it may cause your business to go bankrupt. Or at best, your initial investment will go to waste. Of course, this is a very expensive trial method.

Let's take a quick look at the most commonly used fabrics in the manufacture of fitness apparel. ( However, now you know the critical point. The important thing is not the label on the fabric. It is what the actual content of the fabric is. )

' The best fabric to use for T-shirts is undoubtedly cotton and modal. The addition of 5% elastane to prevent wrinkling and 15-20% polyester to increase durability will give the best results. '

The best choice for T-shirts, sweatshirts and hoodies is a high quality cotton fabric. However, it is not the fabric that matters, but the quality of the fabric. For example, a 160 gram cotton fabric is preferred for a T-shirt. However, the quality of the T-shirt depends on the technology used to produce the cotton fabric. It should be noted that the t-shirt produced using fabric made of 100% cotton fibre will wrinkle very quickly as it does not contain elastane in the fabric content. It is a good choice to add 5% elastane to the cotton fabric to prevent wrinkling of the t-shirt.

Not all cotton fabrics are of the same quality.

Sportswear brands often fall into the low price trap of manufacturers. Most sportswear manufacturers quote prices based on using low quality cotton fabric for T-shirts and hoodies in order to get orders. (We are not even considering that they will be using fabric weighing less than 160 grams, which is the ideal fabric weight for a T-shirt). The T-shirt that will be made from cheap, inferior short fibre, with a sparse knitting technique and no finishing process to ensure the quality of the fabric, will of course be a disposable T-shirt.

Long Fibre Compact Cotton Fabric is the best type of Cotton Fabric. As Conbello Textile, we use Long Fibre Compact (LFC) cotton fabric by default unless we are specifically requested by our customers to use a different type of cotton fabric.

Long fibre compact cotton fabric is considered to be the best type of cotton fabric due to its unique properties and benefits.

Longer Fibre Length: Long fibre compact cotton fabric has longer fibre length than other types of cotton fabrics. This longer fibre length results in a stronger and more durable fabric that is less prone to pilling and snagging.

Higher Yarn Count: Long staple compact cotton fabric typically has a higher thread count than other types of cotton fabrics. This higher thread count means that the fabric is denser and more compact, resulting in a softer and more luxurious texture.

Better Weave: Long fibre compact cotton fabric is woven using a special technique that allows for a tighter weave and a more compact fabric. This tighter weave results in a fabric that is less prone to creasing and easier to care for.

Improved Breathability: Long staple compact cotton fabric is more breathable than other types of cotton fabric due to its unique fibre structure. This improved breathability means that the fabric allows for better airflow and moisture absorption, making it ideal for apparel and textiles that require moisture management.

Increased Durability: Long staple compact cotton fabric is more durable than other types of cotton fabric due to its stronger fibres and tighter weave. This increased durability means that the fabric is less likely to tear or fray quickly, making it an excellent choice for apparel and textiles that require long-term durability.

Better Absorbency: Long staple compact cotton fabric has better absorbency than other types of cotton fabrics due to its unique fibre structure. This better absorbency means that the fabric can absorb and retain moisture more effectively, making it ideal for clothing and textiles that require moisture management.

Overall, long staple compact cotton fabric is considered the best type of cotton fabric because of its unique properties and benefits. Its longer fibre length, higher yarn count, better weave, improved breathability, increased durability and better absorbency make it an ideal choice for apparel and textiles that require high quality and performance.

How to create a successful sportswear brand?

Yes, although it may seem that it has nothing to do with the fabrics used in fitness clothing, it actually does. And we think you should definitely read it to grow your brand. Because you will face the facts and you will see the way out more clearly.

How to create a successful sportswear brand?

How do I start a fitness clothing brand

Which fabric is best for sports?

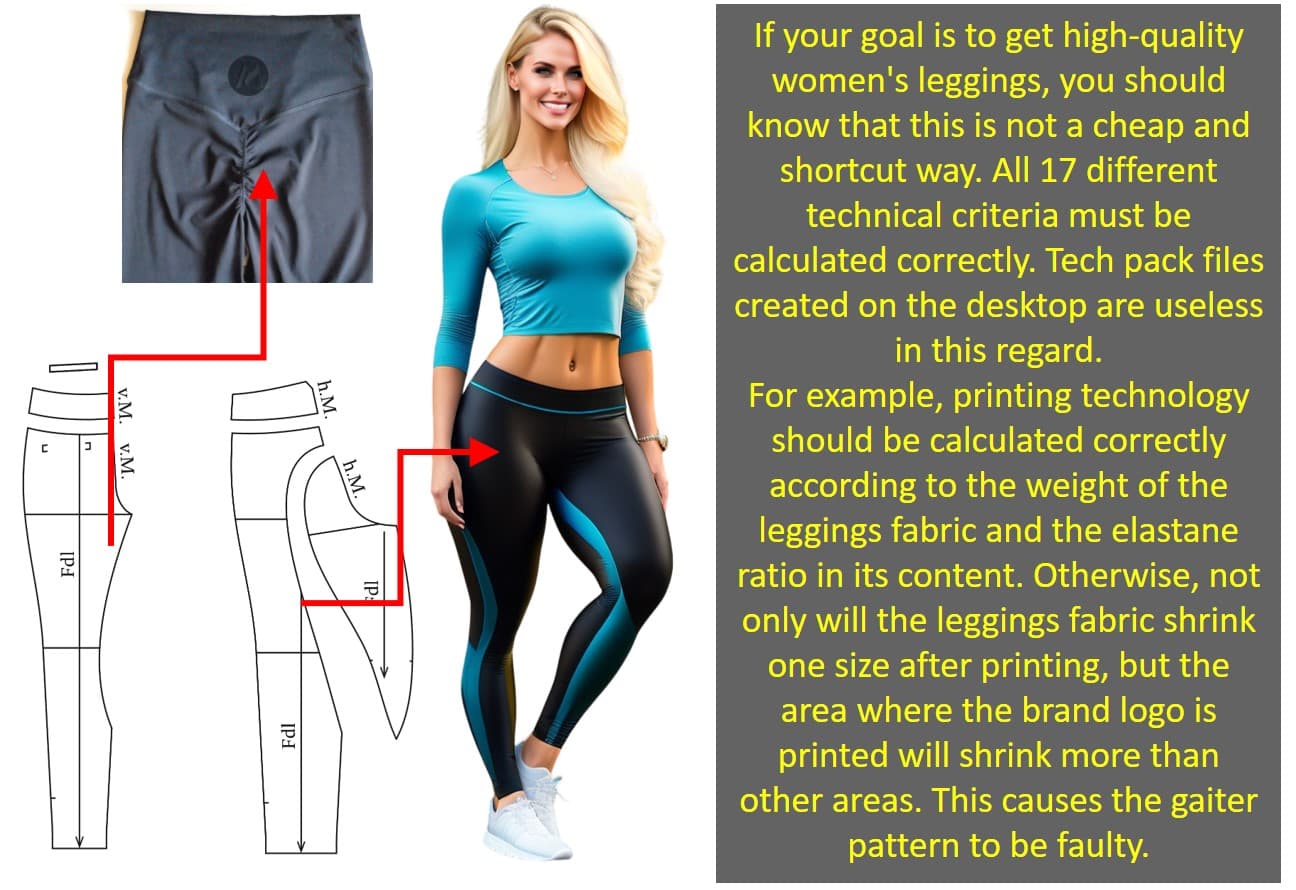

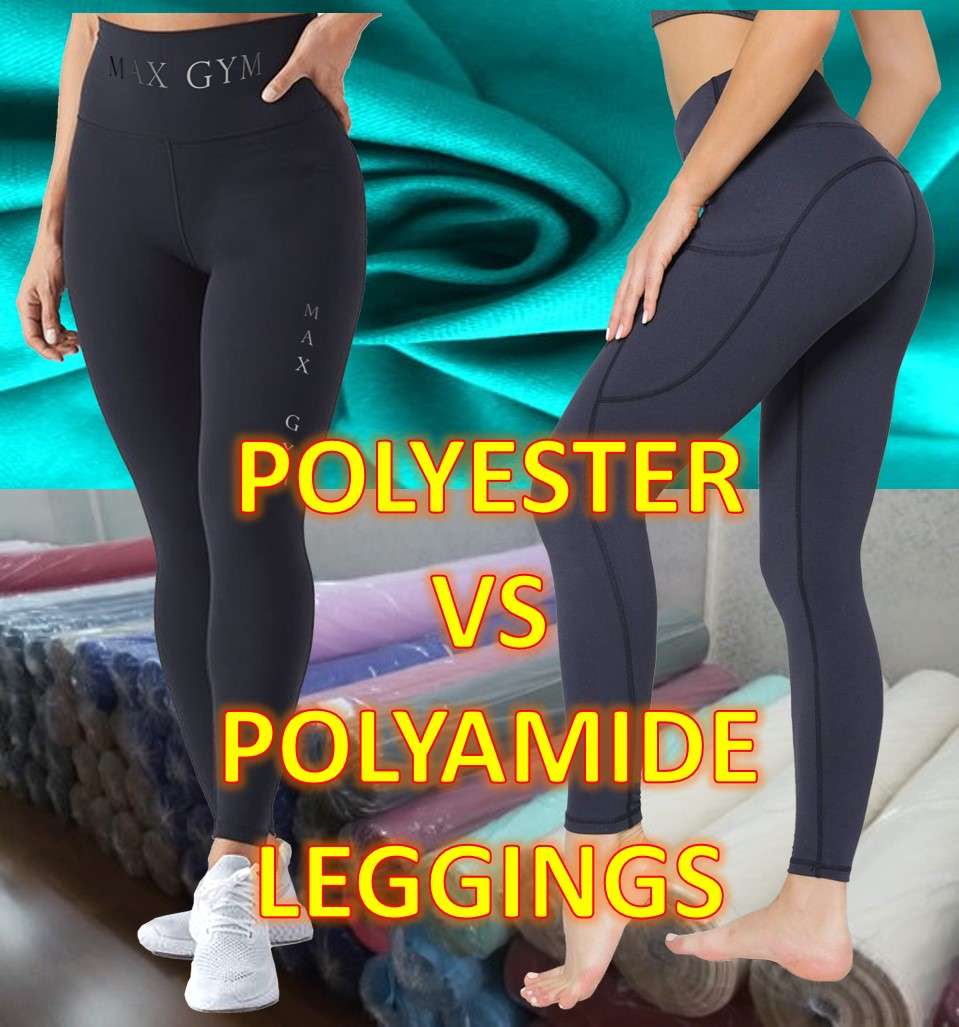

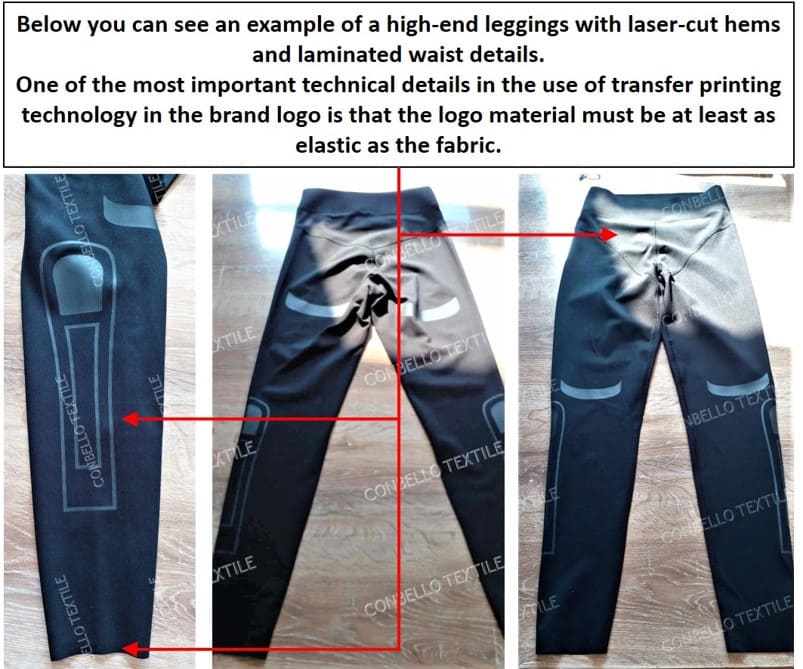

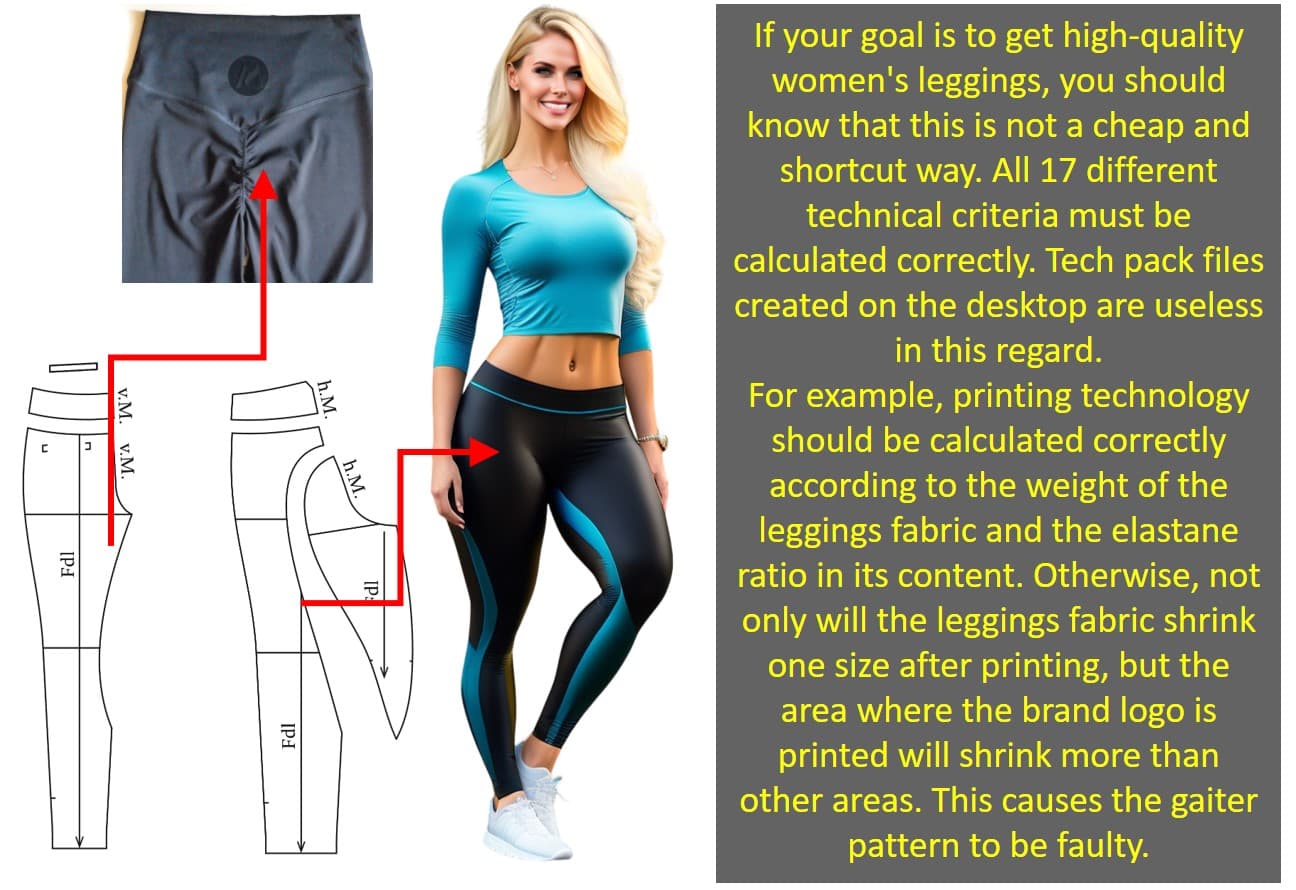

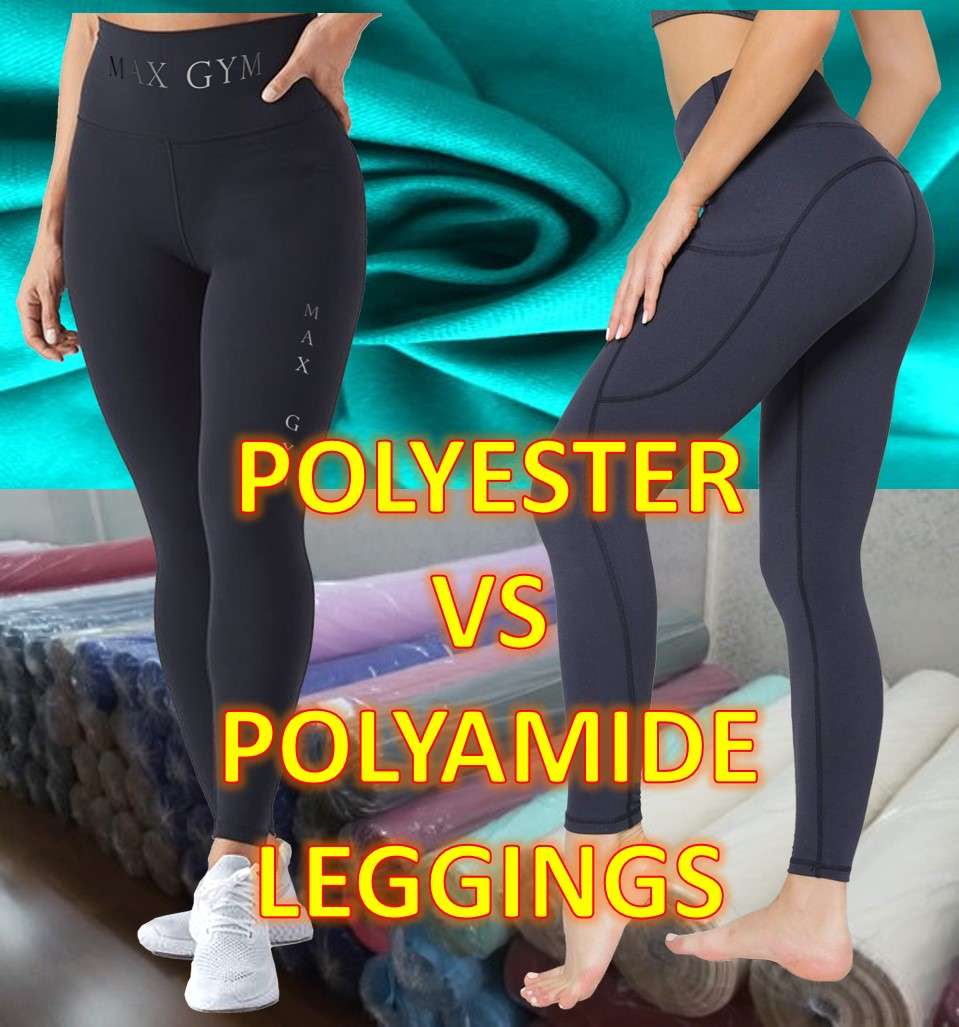

As Conbello Textile, we use approximately 150 types and sub-types of fabrics according to the purpose of use in sportswear. There is absolutely no clear answer to this question. For example, polyester or polyamide fabric, which is often recommended in many places to be used in leggings and sports bras. Really ?. Definitely not. As Conbello Textile, of course, we use polyester and polyamide fabrics of the highest quality and in all weights. However, we also use original cotton fabric in the manufacture of leggings and sports bras. The leggings and other sportswear products we manufacture from cotton fabric have extremely natural and breathable properties. Cotton fabric has an incredible advantage over synthetic fabrics (polyester, polyamide fabric). They do not contain BPA (Bisphenol-A), which is a toxic chemical. Read detailed information about BPA here.

What material is fitness wear?

Fabrics such as Polyester, Polyamide, Cotton, Tencel, Viscose, Bamboo can be preferred. However, do not forget the critical point. It is not what is written on the label of the fabric, but what the fabric actually is. For example, when we test Bamboo fabrics, we see that most of them are a mixture of Bamboo and viscose fabrics. Conbello Textile uses original Anti-bacterial Bamboo fabric fabric.

What fabric is sportswear? / Fabric types such as Cotton, Polyester, Viscose, Tencel can be preferred, but the most important point is that all finishing processes are completed during fabric production. In addition, fabric with different elastane ratio should be used according to the intended use of the sportswear product. In the meantime, what weight the fabric should have in the relevant sportswear product should be calculated clearly and accurately. Conbello Textile will give you technical advice on this and all matters.

Our customers who have had painful experiences with their first investments

We have clients that we have worked with for nearly 25 years since the beginning of their business. Therefore, we gain many new customers thanks to the recommendations of these old friends.

Many of our customers, who came with the advice of our old customers or found us from scratch, are people who have experienced bitter experiences above. Many of our customers have lost their initial investment, thanks to companies that are inexperienced or look at sportswear manufacturing as just making money.

Does fabric selection really matter?

In a word, yes, it is a very important and vital issue.

It is vital for the future of your sportswear brand that you read the following information about fabric frauds in order to manufacture cheap and poor quality products in clothing manufacturing.

Problems frequently encountered in the manufacture of cheap and poor quality fitness clothing (Only problems about fabric quality are discussed in this article.)

1) Fabric production fraud: The fabric that is said to be used is not the fabric that is actually used. For example, polyester fabric is used in a legging that is supposed to be polyamide. We come across this type of fraud more often than you might think. Unfortunately, we often find this fraud when testing fabric samples or finished products sent to us by customers. Or when we test the fabric that is supposed to be bamboo fabric, we find that viscose and cotton fibres are usually mixed with bamboo fabric to reduce costs. Polyamide fabric is more expensive than polyester fabric. Considering the fact that polyamide fabric is used, the customer pays the high price, but unfortunately, what he or she gets in return is not a high quality polyamide leggings, but only a simple leggings made of the cheapest polyester.

2) Fabric weight fraud: The fabric weight stated is not the actual weight of the fabric used. For example, a T-shirt that should be oversized and made from 100% cotton at 240 gsm will be made from 200-220 gsm fabric to reduce costs. As the main aim of a manufacturer who decides to produce cheap and poor quality sportswear is to reduce costs, you may have guessed that the fabric used will not be 100% cotton. However, not all fabrics that are made from 100% cotton are of the same quality. A 100% cotton T-shirt fabric will use short staple cotton fibres. A high quality 100% cotton fabric will use long staple cotton fibres.

3) Failure to complete all stages of fabric production: Failing to apply the final finishing process to fabrics used to make apparel. For example, colour fastness and colour fixation finishes are not applied.

A poor quality and cheap fabric starts to deteriorate in the first washes, even after the product has been worn for a while, regardless of the printing system you apply on it. The color of the print applied to the fabric will fade quickly. This color fading/deterioration, which can be seen very quickly in print, ultimately leads to wastage of the entire product!

Of course, these are just the beginning. When we start working together, you will realize that the subject of fabric selection is very deep and important.

It will be useful for you to review our related pages below.

Support for startup Fitness clothing brands