What type of print is best for sportswear?

Printing Technologies Used in Sportswear and Clothing

Many clothing brands rush into low-priced garment orders without asking why they're so cheap—often overlooking hidden flaws in fabric, stitching, and especially print quality. And they should not forget that as a result, they have to risk serious financial losses as well as damaging their brand reputation.

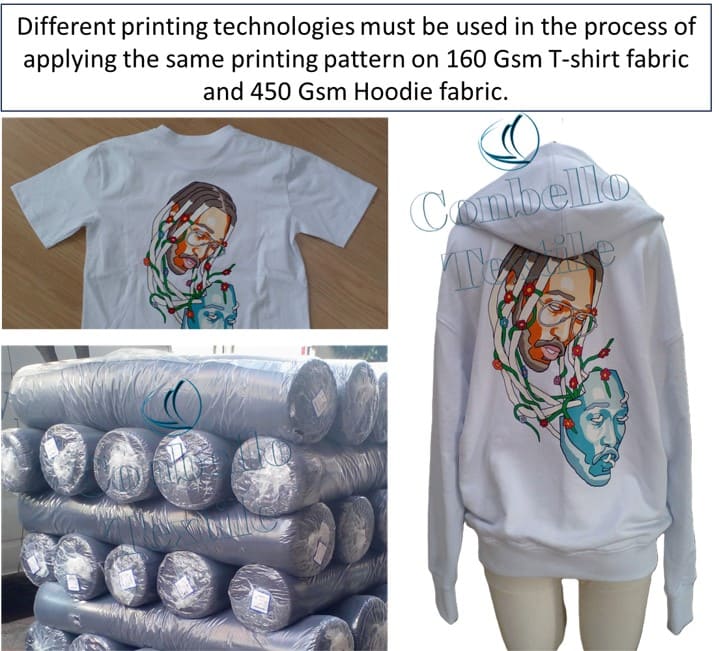

The issue of printing on clothes is a much more comprehensive and detailed subject than it is thought, and it should be applied according to the technical characteristics of the fabric.

Conbello Textile uses all printing techniques of printing techniques on clothing with the highest quality. All types of screen printing (12 full colors) application, transfer printing, silicone printing, digital sublimation printing, digital printing, high printing, embroidery types.

In addition to the basic printing technologies frequently used in clothing, Conbello Textile successfully uses all printing methods, including real silicone printing and nanotechnological printing.

Printing on clothing is a far more complex and detailed topic than often perceived

Successful printing depends heavily on the technical characteristics of the fabric. There are countless articles online about printing methods used in sportswear—but is the topic really that simple?

At Conbello Textile, we employ all advanced printing technologies for apparel with unmatched quality

This includes screen printing (up to 12 full colors), transfer printing, silicone printing, digital sublimation, digital printing, high-density printing, and various embroidery techniques.

Avoiding the Low-Price Trap in Fitness Apparel Printing

Many sportswear brands that don't understand the difference between high-quality and low-quality printing fall into the cheap price trap—and ultimately lose brand value. As a sportswear designer or brand owner, it’s not just what you do but how you do it that determines the final product’s quality.

How to Choose the Best Printing Technology for Sportswear

Selecting the right printing method and applying it correctly is a critical technical decision. This depends on

Fabric Type such as cotton, polyester, polyamide (nylon), viscose, Tencel etc

Fabric Construction such as knitted, woven, double-sided

Fabric Weight and Thickness ranging from lightweight to heavy fabrics such as 350–450 GSM

Elastane Content the stretch fiber percentage affecting print durability

End-Use Environment such as gym wear, outdoor conditions, cold or hot climates, or areas with high friction

Please click the link to get fast and accurate information about clothing printing technologies.

Sportswear brands that do not know the difference between high quality printing and low quality printing often fall into the low price trap.

How to avoid the low price trap in fitness apparel

As a sportswear designer, it is not what you do, but how you do it.

Which printing technology to use and how to apply it to which garment is one of the technical issues that leaves no room for error, but unfortunately is almost always overlooked (or especially overlooked?).

What is the best printing method for sportswear?

Printing on Synthetic Sportswear Fabrics Challenges and Solutions

Screen printing on synthetic fabrics such as polyester and nylon, commonly used in sportswear, requires technical expertise and advanced technology. For instance, when applying light color prints on dark polyester garments, the fabric color can bleed into the print. Specialized primer layers and advanced inks prevent this issue. Cheap, low-quality sportswear may seem affordable initially, but over time, the cost of poor durability and fading far outweighs investing in high-quality printing.

Why Application Technique Matters as Much as the Printing Method

Even the best printing technology fails without proper application. This is a common pitfall for many startup and mid-sized sportswear brands that focus only on price. Low-cost manufacturers often sacrifice quality to cut costs, causing fading, cracking, and poor brand representation.

Screen printing on synthetic fabrics such as polyester and polyamide (nylon), which are frequently used in sportswear, requires deep experience and technology. In light color screen printing application on dark color fabrics, the fabric color quickly penetrates into the print color (brand logo or any print). There are special technological methods to prevent this. The money spent on cheap and low quality sportswear is actually much higher than the money spent on high quality sportswear.

As important as the printing technique to be applied to the garment (brand logo printing or any other printing on the garment) is the correct application of the printing technique.

Click on the image below to see Conbello Textile's Hyper SC printing technology, designed for high-quality, demanding garments.

You must be prepared for the devastating consequences that can occur when you lack experience with different printing systems or fail to pay attention to delicate technical details that can easily be overlooked.

What are the most commonly used printing techniques in fitness clothing?

What are the most commonly used brand logo printing methods in cotton and polyester fabric sportswear?

Let's start with screen printing, one of the most commonly used printing techniques. It can be applied to both cotton fabric and polyester fabrics. Really ?. The answer is both yes and no. Cotton and Polyester fabrics can be screen printed using a variety of inks, including plastisol, water-based and etching inks.

Before applying screen printing to a dark polyester-based fabric, a primer layer must be used first. When the liner ink layer dries, it will shrink slightly. For this reason, special attention should be paid to the mold size to be used in the screen printing to be applied on the primer layer. However, if the elastane content of the polyester fabric to be screen-printed is high (usually 10% or higher), you should prevent it from cracking after the ink dries. In addition, screen printing inks have reached almost unlimited varieties thanks to developing technology. This diversity has made things even more complicated. If the screen printing ink type is not chosen exactly correctly, the dye will separate from the fabric surface, fade and crack shortly after the drying process.

If you prefer plastisol type printing, which is cheap and very easy to apply, you should compromise on high quality. Eventually it will look like a thick coating on the fabric. When the elastane ratio in the fabric content is not calculated correctly, it is obvious that the applied print will not satisfy the appearance. If you want to screen print on a thick cotton or polyester fabric with a hairy inside such as 350-450 Gsm and you have a printing pattern consisting of 4-6 colors, your experience must be at a very high level. Otherwise you have to bear the consequences. Some of the polyester fabrics are produced with a special coating. When screen printing is applied to this fabric, it is obvious that it will be a waste of clothing.

Do you want to apply light color screen printing on a dark polyester fabric ? Water-based inks are also a good option as they provide a softer hand feel and are more environmentally friendly than plastisol inks. You have to be very careful about how to apply it. If you bought a large amount of fabric to apply abrasion type screen printing without testing the fabric beforehand, you are in serious trouble now. Discharge inks are used to create a soft, breathable print on dark-colored polyester fabrics.

Correctly applying the printing technique is paramount when printing on clothes, even more so than the technique itself.

Another technical issue that is just as important as the printing system applied to the garment (perhaps even more important) is the correct use of the printing technique applied. This is the pitfall that most start-up and mid-sized sportswear brands fall into. They get prices for sports-fitness apparel from different manufacturers and focus on the low price. When they place a wholesale order with the lowest priced manufacturer, they don't realize that they are actually losing out. This is because the fitness apparel manufacturer has to compensate for the low price by sacrificing quality in many ways because of the low manufacturing price.

Overview of Common Printing Techniques Used in Sportswear and Brand Logo Printing

Screen Printing

Versatile and widely used for both cotton and polyester fabrics

Ink types include plastisol, water-based, and discharge inks

For dark polyester, a primer layer is essential before printing

High elastane content above 10 percent requires special ink selection to avoid cracking

Water-based screen printing offers a soft feel and eco-friendly option with vibrant colors

Screen printing delivers high durability and long-lasting vivid colors, ideal for t-shirts, hoodies, leggings, sweatshirts, and other sportswear

Plastisol inks are cheaper but create a thick plastic coating and contain chemicals, less ideal for high-end apparel

Direct to Film DTF Printing

Affordable for small production runs under 500 pieces

No printing plates needed, enabling unlimited color variety

Creates a plastic layer on the fabric surface and doesn’t penetrate the textile, making it less durable

Best suited for promotional apparel and not recommended for premium sportswear

Direct to Garment DTG Printing

Prints designs by spraying ink directly onto garments

Works best on 100 percent cotton fabrics

Applying DTG on cotton/polyester blends leads to poor print quality, fading, and peeling after washing

Requires post-print chemical treatment and curing in a drying oven to ensure ink penetration

Popular for full-color, high-detail prints on light-colored fabrics

Heat Transfer and Sublimation Printing

Frequently preferred for all fabric types, including cotton and polyester

Sublimation is especially effective on polyester fabrics, producing vibrant, durable prints that become part of the fabric

Heat transfer offers many variations but generally does not match the quality of water-based screen printing for premium sportswear

Ideal for complex designs, holographic effects, 3D textures, and brand logos

Specialty Techniques Embossed Print Silicone Print Rubber Print Reflector Print

These techniques add unique textures and visual effects to sportswear

Conbello Textile uses custom silicone prints in equestrian leggings and other specialized garments

High-quality machinery and expert application are essential for flawless results

These methods are increasingly used for brand differentiation and enhancing sportswear aesthetics

Embroidery

Besides printing, embroidery remains a classic and premium method for branding sportswear

Techniques include standard embroidery, 3D embroidery, and patch embroidery

Special threads like glittery or reflective threads add luxury and eye-catching details

Commonly used for small logos but also suitable for larger decorative elements

Key Technical Tips for Sportswear Printing

Always test fabric compatibility and elastane content before production

Select ink types based on fabric type, weight, and stretchability

For dark synthetic fabrics, apply a primer or liner layer before the main print

Avoid plastisol or thick coatings on highly elastic fabrics to prevent cracking

Ensure drying and curing processes are strictly followed for durability

Invest in high-quality fabrics and inks to maximize print longevity

Why Choose Conbello Textile for Your Sportswear Printing Needs

With deep industry knowledge and advanced technology, Conbello Textile ensures your fitness apparel stands out for

Superior print durability and colorfastness

Tailored printing methods optimized for every fabric and design

Support for startups and established brands to grow with confidence

Sustainable and eco-friendly printing options available

For personalized advice on the best printing methods for your brand and products, contact Conbello Textile anytime

1) Direct to film (DTF) printing is an affordable solution for small production runs. For example, for orders of less than 500 pieces. The reason for the low cost is that there is no need to produce printing plates. . An unlimited variety of color printing is available. However, DTF printing does not penetrate the fabric of the T-shirt and remains only as a coating on the surface of the fabric. In other words, DTF printing is a plastic that is bonded to the fabric. It can be used on low quality promotional apparel such as t-shirts, hoodies, leggings. DTF printing technique is not used on high quality sportswear.

2) DTG (Direct to Garment Printing) system, as the name suggests, is applied by spraying ink through a printer onto the garment. However, direct-to-garment printing can only be used on cotton sportswear. Unfortunately, the most common fraud in printing technology to reduce the overall cost of sportswear is to increase the polyester ratio by reducing the cotton ratio in the fabric when applying DTG printing. In other words, DTG printing is applied to cotton/polyester blends. DTG printing can also be applied to cotton fabrics containing polyester, but the print quality will be extremely low. Both the appearance will not be vivid and will separate from the fabric surface after washing, and the print colors will fade. After DTG (Direct to Garment Printing) application, it is necessary to use a special chemical and keep it in a drying oven for 80 seconds to allow the colors to penetrate the fabric.

2) SCREEN PRINTING: The screen printing system ensures the highest quality and full permanent print quality, of course, if the right technique is used. At Conbello Textilel we use completely organic water based screen printing. It is common to use plastic inks to make screen printing even cheaper. However, plastic-based inks contain toxic chemicals. In addition, screen printing with plastic inks looks like a plastic coating on the fabric surface, as in DTF printing. This is because it does not penetrate the fabric. For example, it is just plastic stuck to a T-shirt. As a result, plastic screen printing has a cheap but inferior look. It should also not be used, especially on children's products. For high production quantities (1000-2000 and above) with 3-4 or more colors, water-based screen printing will of course be cheaper and above all very high quality. The cost of screen printing applications consisting of one or two colors is much lower than the cost of dtf or dtg printing. In addition to the low cost of screen printing, the most important difference is that it is incomparably higher quality than other printing techniques.

Before screen printing on a dark polyester-based fabric, a primer must be applied first. (The most important technical issue to be considered when screen printing on white color polyester fabric is the ink selection according to the elastane content of the fabric and the weight of the fabric. Otherwise, the ink will separate from the fabric after drying, fade and crack). When the primer ink layer dries, it will shrink a little. For this reason, special attention should be paid to the size of the stencil to be used in screen printing to be applied on the primer layer. However, if the polyester fabric to be screen printed has a high elastane content (usually 15% and higher), you should prevent it from tearing after the ink dries. In addition, screen printing inks have reached an almost unlimited variety as the technology has evolved. This variety has made things even more complicated. If the screen printing ink is not chosen properly, the ink will separate from the fabric surface, fade and crack soon after drying.

The fading of both fabric and print colors depends entirely on the quality of the fabric and the print. Screen printing (water-based-organic) is the best quality printing that can be used on clothing such as t-shirts, hoodies, sweatshirts and its colors will not fade or yellow after exposure to sun or washing. In addition to all these, since there will be no thickness on the fabric, no touch will be felt when touched by hand. Moreover, since it penetrates into the fabric (if the appropriate silk count, screen, correct drying temperature - time and printing force are applied), it does not separate from the fabric.

In sportswear fashion such as T-shirts, Hoodies, Leggings, there are more printing systems for your brand's logo printing than you might think. We think that we can start to examine these printing techniques briefly.

Among the most well-known printing techniques, we can count Screen printing, Heat transfer, Flexo. Of course, even these print types are divided into many types among themselves. Regarding printing systems, you can contact Conbello Textile at any time about which printing technique should be used for your brand and sportswear products.

Of course, although it is not considered a type of printing, it is necessary to review the embroidery application, which is frequently used in sportswear.

An example of nanotechnology printing systems, T-shirt printing activated by water or sweat

Screen Printing : If you want to get more detailed technical information about this subject, please click. Plastic paint is definitely the most commonly used type of ink due to its cheapness. However, this dye does not penetrate the fabric and only covers it. So think of something like covering the top of the t-shirt fabric with your pattern.Of course, it is preferred not only because it is cheap, but also because it is very easy and effortless to apply. However, if you want top segment quality printing for your sportswear brand, water-based organic screen printing will undoubtedly be your first choice.

Although it is very popular to use the screen printing technique in sportswear, great attention should be paid to the pattern design and color transitions for a high quality print.There are different application techniques such as plastisol, water-based and etching. However, when applying a pattern with highly detailed color transitions with screen printing technique, it is very important that the silk pattern is produced without errors.

Screen printing inks come in different types, including water-based, solvent-based, and UV-curable. Water-based inks are environmentally friendly and easy to clean, but may require longer drying times. In addition, the application of water-based screen printing is more difficult than plastic screen printing and requires experience. Solvent-based inks are known for their durability and fast drying properties, but may contain harmful chemicals. UV-curable inks harden instantly when exposed to ultraviolet light and although the result is a durable, high-gloss surface, great care must be taken with post-press drying.

Screen printing inks can also be added in different colors including opaque, translucent and metallic hues, as well as embellishments such as gilding and glitter to create gorgeous looks.

Click on the image below to watch a short video on Conbello Textile fitness apparel manufacturing

Heat Transfer & Sublimation You can consider it as a frequently preferred printing system, as it can be easily applied to all fabric types, whether cotton or polyester. Of course, this printing technique has many variations in itself. However, if you are considering a top segment sportswear in terms of quality, your choice will undoubtedly not be the Heat transfer printing system. As we apply all printing systems (including heat transfer) known as Conbello Textile, we also develop and apply special printing techniques in line with the technical needs of our customers. Conbello Textile successfully uses this printing technique in brand logo applications in unlimited colors, 3D, different appearances such as holograms and in different thicknesses. In addition, we use the full color non-toxic transfer printing method on roll fabric and piece fabric in our production.

We use the unique high quality silicone print developed by Conbello Textile in equestrian leggings and equestrian clothing.